What is Mild Steel SHS? 5 Smart Uses You Need to Know

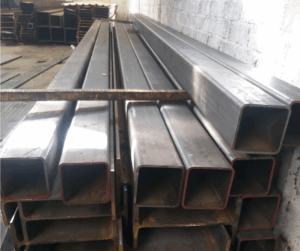

Mild steel SHS is one of the most widely used materials in modern construction, engineering, and fabrication. SHS stands for Square Hollow Section, and when made from mild steel, it offers a strong, versatile, and cost-effective solution for a wide range of structural and aesthetic applications.

Whether you’re a builder, fabricator, designer, or project manager, understanding how mild steel SHS works—and where it performs best—can help you make more informed decisions and save on both materials and labor.

What Does “Mild Steel SHS” Mean?

Mild steel is a low-carbon steel with excellent weldability, machinability, and affordability. It contains only about 0.05–0.25% carbon, which makes it softer and more ductile than high-carbon steels. This composition allows mild steel to bend and form without cracking.

When mild steel is used to make SHS (Square Hollow Sections), the result is a hollow steel tube with equal width and height on all sides, and typically with a clean, flat finish. This geometric uniformity makes mild steel SHS easy to work with and ideal for construction.

Why Choose Mild Steel SHS?

There are several compelling reasons why mild steel SHS is such a popular material in both residential and commercial projects:

1. Excellent Strength-to-Weight Ratio

Even though mild steel isn’t as strong as high-tensile steel or stainless steel, it still provides solid structural support for most low to medium load-bearing needs. SHS profiles are particularly efficient in resisting compression, torsion, and bending—making them a great choice for framework.

2. Easy to Cut, Weld, and Fabricate

Because of its low carbon content, mild steel SHS can be cut and welded with standard equipment. It doesn’t require preheating or post-weld treatments in most situations. This lowers fabrication costs and shortens lead times.

3. Cost-Effective Material

Compared to stainless steel or aluminum, mild steel is significantly cheaper, especially in bulk. For builders and fabricators on a budget, mild steel SHS provides a durable, dependable alternative without sacrificing performance for many structural needs.

4. Uniform Shape and Appearance

The square profile of SHS means all four sides are of equal dimension, offering symmetry and balance in construction. It also makes it easier to join, align, and stack with other materials during installation.

5. Wide Range of Sizes and Thicknesses

Mild steel SHS is available in an extensive selection of sizes and wall thicknesses. This makes it easy to find the exact specification needed for various projects—from light-duty shelving systems to major commercial infrastructure.

Typical Applications of Mild Steel SHS

Mild steel SHS is one of the most versatile hollow sections on the market. It is widely used across industries because it’s strong, economical, and flexible. Some of the most common applications include:

Structural Framing

One of the primary uses of mild steel SHS is in structural framing—particularly for commercial and industrial buildings. Its symmetrical square profile provides excellent strength-to-weight ratio and consistent load-bearing performance. This makes it an excellent choice for support beams, columns, and roof trusses in warehouses, low-rise buildings, carports, sheds, and even modular construction. Its flat surfaces allow for clean, strong joints with minimal material wastage, which is highly valued in cost-sensitive projects.

Fencing and Gates

Mild steel SHS is frequently used to fabricate modern fencing, gates, security grilles, and balustrades. Its square profile not only delivers strength and rigidity but also gives a sleek, modern appearance that suits both residential and commercial properties. Fabricators appreciate its ease of cutting, drilling, and welding, while property owners benefit from its durability and ability to withstand daily wear and tear. It can be galvanized or powder-coated for improved weather resistance and aesthetic appeal.

Furniture and Interior Fixtures

The clean, geometric design of mild steel SHS makes it highly desirable for modern industrial-style furniture, shelving systems, and retail fit-outs. Designers use it for table frames, bench legs, and modular shelving units, often combining it with wood, glass, or recycled materials. It holds up well under weight and stress, and its surface can easily be painted, polished, or powder-coated to match any interior concept—from rustic to contemporary.

Trailers and Vehicle Chassis

In the transportation and automotive industries, mild steel SHS is often found in trailer frames, caravan bases, and lightweight chassis structures. It provides high strength and vibration resistance while keeping the overall frame weight manageable. Welders appreciate how easy it is to fabricate and reinforce, making it suitable for off-road trailers, farm utility vehicles, and transport platforms that operate in rugged environments.

Agricultural Machinery and Frames

On farms and in rural settings, mild steel SHS is widely used to build greenhouse frames, irrigation supports, tool sheds, livestock enclosures, and equipment frames. Its square design provides a stable base for mounting panels, mesh, or roofing materials. It also offers long-term durability and resistance to bending, making it ideal for withstanding harsh outdoor conditions, heavy use, and rough handling.

Coating and Protection Options

One downside to mild steel is its susceptibility to rust and corrosion. Because it lacks the chromium content found in stainless steel, protective coating is often necessary—especially in outdoor or high-moisture environments.

Common protective finishes for mild steel SHS include:

- Hot-dip galvanizing (zinc coating to resist rust)

- Powder coating (for color, texture, and protection)

- Painting (economical, but requires maintenance)

- Oil or wax coating (temporary protection during storage or transport)

Regular inspection and recoating may be required if mild steel SHS is exposed to the elements over time.

Standard Mild Steel SHS Sizes (Australia/Global)

Mild steel SHS comes in various sizes to suit different design needs. Here are some commonly available dimensions (width × width × wall thickness):

- 20 × 20 × 1.6 mm

- 40 × 40 × 2.0 mm

- 50 × 50 × 3.0 mm

- 75 × 75 × 4.0 mm

- 100 × 100 × 5.0 mm

- 150 × 150 × 6.0 mm

These are typically manufactured according to AS/NZS 1163 standards in Australia or EN 10219 in Europe. Custom lengths and coatings are also available from most steel suppliers.

Mild Steel SHS vs Stainless Steel SHS

Choosing between mild steel and stainless steel SHS depends on your project’s priorities:

| Feature | Mild Steel SHS | Stainless Steel SHS |

| Cost | More affordable | More expensive |

| Rust resistance | Needs coating | Naturally corrosion-resistant |

| Weight | Slightly lighter | Heavier due to density |

| Aesthetics | Neutral, paintable | Clean, modern finish |

| Maintenance | Needs periodic care | Very low maintenance |

| Applications | General, indoor/outdoor | Premium, exposed structures |

If you’re building something that won’t be exposed to extreme weather or corrosive chemicals, mild steel SHS is often the most economical and effective choice.

Final Thoughts: Is Mild Steel SHS Right for You?

If you’re looking for a structural material that balances strength, affordability, and ease of use, mild steel SHS is hard to beat. It’s a time-tested option trusted by builders, engineers, and fabricators around the world.

Before purchasing, always consider the environment, required load strength, and whether protective coating is necessary. With the right preparation, mild steel SHS can last for decades—even in tough working conditions.

Need Mild Steel SHS? Get a Fast, Free Quote

At [Your Company Name], we stock a wide range of mild steel SHS in various sizes, wall thicknesses, and finishes. Whether you need standard lengths or custom cuts, we’re here to help.

Send us your drawings or specifications today and get a free quote with no obligation.

You can find out more about us at our Fanpage Lintel Steel.