Unequal Angle Steel: Finishes, Grades and 5 Ways to Pick

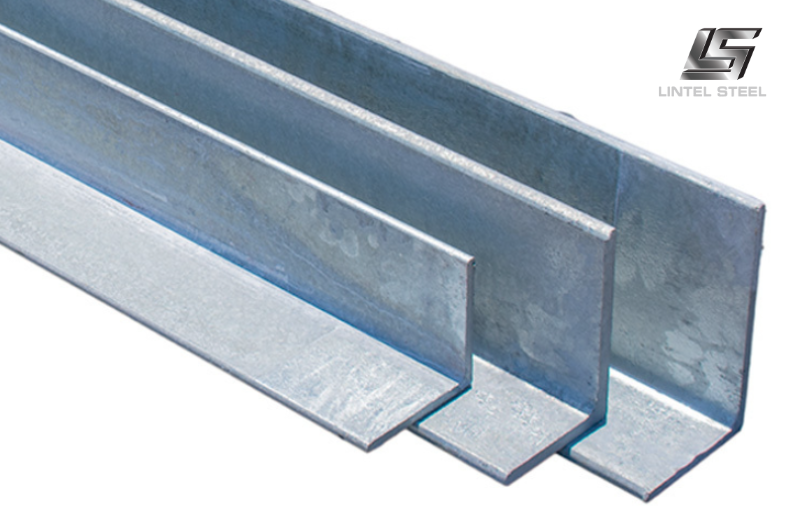

When it comes to steel framing and structural support, unequal angle steel stands out as one of the most practical and efficient options in the construction and fabrication industry. Unlike equal angle steel, where both legs are the same length, unequal angles have one leg longer than the other — giving engineers and builders more flexibility in handling loads and space constraints.

What Is Unequal Angle Steel?

Unequal angle steel is a type of steel section with two legs of different lengths, forming an “L” shape that provides strong support and stability in various applications. It’s typically manufactured from mild steel or stainless steel and can be hot-rolled, cold-rolled, or galvanised depending on the intended use.

The most common dimensions include:

- 40 x 25 x 3 mm

- 50 x 30 x 5 mm

- 65 x 50 x 6 mm

- 75 x 50 x 6 mm

- 100 x 75 x 8 mm

These size variations allow unequal angle steel to perform well in both light and heavy-duty structures.

Why Choose Unequal Angle Steel?

There are plenty of reasons why unequal angle steel has become such a reliable favorite among builders, engineers, and fabricators. Its simple yet asymmetrical design gives it a unique combination of strength, versatility, and adaptability that other structural sections often can’t match.

Unlike equal angle steel, where both legs share the load evenly, unequal angle steel is specifically engineered to provide superior strength in one direction. This feature allows it to handle uneven loads, making it a smart choice in structures where the weight distribution or design geometry isn’t perfectly balanced.

1. Flexible Design and Engineering Freedom

One of the biggest advantages of unequal angle steel is its flexibility in design. The varying leg lengths allow architects and engineers to adapt the section to different configurations without adding unnecessary weight or material. Whether it’s used in frames, supports, or custom reinforcements, the unequal profile gives more control over how and where the load is distributed.

For example, in industrial machinery frames or warehouse shelving systems, unequal angles allow for stronger connections without sacrificing space efficiency. The ability to orient the longer leg in the direction of higher stress also gives structural designers more creative freedom without compromising stability.

2. Superior Load-Bearing Capacity in One Direction

Because of its asymmetrical geometry, unequal angle steel excels in situations where the load is concentrated or applied from one side. The longer leg provides additional resistance to bending and torsion, helping to prevent structural deformation even under heavy stress.

This makes it ideal for cantilevered structures, crane brackets, or frames supporting uneven weight, where traditional equal angles might not provide the same directional strength. In essence, the unequal design allows engineers to fine-tune the strength-to-weight ratio, improving efficiency and safety.

3. Easy to Fabricate and Weld

Fabricators appreciate unequal angle steel because it’s straightforward to cut, drill, and weld. It pairs easily with other steel sections such as SHS (square hollow sections), RHS (rectangular hollow sections), and flat bars, which makes it highly adaptable in workshop and on-site applications.

Whether you’re working on custom brackets, frames, or reinforcements, unequal angles allow for quick modification and easy integration into larger structures. Its excellent weldability also ensures that joints remain strong and durable even in demanding environments.

4. Wide Range of Surface Finishes

Another benefit of unequal angle steel is the variety of finishes available.

- Black mild steel offers affordability and easy machinability for indoor use.

- Hot-dip galvanised unequal angle steel provides long-term corrosion protection, perfect for outdoor and coastal applications.

- Stainless steel unequal angle steel delivers both strength and an attractive aesthetic, ideal for architectural or decorative purposes.

These finish options make it easy to match the right material to your project’s environmental and visual requirements.

5. Cost-Effective and Readily Available

Because unequal angle steel is mass-produced in standard lengths and sizes, it’s both cost-effective and widely available across Australia. For example, standard stock lengths of 6.0 m and 9.0 m are common, with thicknesses ranging from 3 mm to 12 mm. This makes sourcing and transport straightforward — an important factor for large construction projects that demand consistency and supply reliability.

6. Strong Performance in Harsh Conditions

When galvanised or stainless grades are used, unequal angle steel performs extremely well in outdoor, marine, and industrial environments. It resists corrosion, warping, and fatigue over long periods, making it a dependable choice for exposed structures or frameworks subjected to weather and mechanical stress.

Applications of Unequal Angle Steel

Because of its adaptability, unequal angle steel is used across a wide range of industries:

- Structural framing in buildings and bridges.

- Support brackets and frames in construction and machinery.

- Shelving systems and storage racks.

- Vehicle and trailer frames where space and weight balance are critical.

- Marine and outdoor structures, when galvanised or stainless steel is used.

This versatility makes it a popular choice among builders, fabricators, and engineers looking for a reliable yet adaptable material.

Unequal Angle Steel vs. Equal Angle Steel

When choosing between unequal angle steel and equal angle steel, understanding their differences is key to making the right decision for your project. Although both belong to the same family of structural steel sections and share the classic “L” shape, their proportions — and therefore their performance — vary in important ways.

1. Geometry and Structure

The most obvious distinction lies in the leg lengths.

- Equal angle steel has both legs of the “L” equal in size — for example, 50 x 50 x 5 mm.

- Unequal angle steel, on the other hand, has one leg longer than the other, such as 75 x 50 x 6 mm.

This seemingly small difference in geometry changes how the steel behaves under load. Equal angles distribute stress uniformly, while unequal angles provide asymmetrical load-bearing strength — a major advantage when one side of a frame or structure experiences higher forces.

2. Load Distribution and Strength

Because of its asymmetry, unequal angle steel is better suited for applications where strength is required in one direction. It provides enhanced resistance against bending and twisting when loads are applied unevenly — such as in support beams, brackets, or edge reinforcements.

In contrast, equal angle steel works best in balanced structures where forces act evenly from both sides. For instance, equal angles are common in general frameworks, trusses, or welded assemblies where symmetry and uniform support are essential.

So if your project involves uneven loading, complex geometry, or limited space, unequal angle steel is usually the smarter and more efficient choice.

3. Design and Space Efficiency

Unequal angle steel offers more design flexibility for engineers and builders. Its unequal legs can fit into tight corners or irregular spaces without compromising structural integrity. This makes it ideal for machine frames, towers, vehicle structures, and construction supports where one side of the member needs to extend further to connect with another part.

Meanwhile, equal angle steel tends to take up more space symmetrically, which can limit its adaptability in intricate designs.

4. Cost and Material Optimization

From a cost perspective, unequal angle steel can also be more material-efficient. By placing extra steel only where strength is needed most, designers can minimize excess weight — reducing material waste and total project cost.

This approach is particularly beneficial in large-scale builds, such as warehouses or bridges, where optimizing every kilogram of steel can translate into significant savings. Equal angles, while easier to produce, don’t offer the same opportunity for targeted reinforcement.

5. Typical Applications

Here’s where each type shines:

- Unequal Angle Steel – used in crane structures, shipbuilding, transmission towers, heavy machinery frames, and architectural supports where directional load strength matters.

- Equal Angle Steel – used in roof trusses, shelving systems, lightweight frames, and general construction where the loads are evenly spread.

Essentially, unequal angle steel is the go-to when the project demands precision, directional reinforcement, and smart use of space. Equal angles remain a solid choice for standard, uniform load-bearing applications.

6. Aesthetics and Finishing

In architectural and design contexts, unequal angle steel also provides a subtle but practical visual benefit — the longer leg can be hidden or exposed strategically to suit design aesthetics. With finishes like galvanised, powder-coated, or polished stainless, it can be both functional and visually clean.

Equal angle steel, being more symmetrical, fits well where visual balance is key — but when performance comes first, the asymmetric form of unequal angle steel wins.

Common Finishes and Grades

Unequal angle steel is available in several finishes to suit different environments:

- Mild steel unequal angle – cost-effective and easy to weld.

- Galvanised unequal angle steel – provides corrosion protection for outdoor or marine environments.

- Stainless steel unequal angle – excellent durability and sleek appearance for architectural applications.

Popular grades include Grade 250, Grade 350, and 316 stainless steel, depending on whether strength or corrosion resistance is the main priority.

How to Choose the Right Unequal Angle Steel

When choosing unequal angle steel, consider the following factors:

- Load requirements – determine the thickness and size needed for safe support.

- Environment – use galvanised or stainless finishes for outdoor use.

- Joining method – check weldability and drilling ease.

- Standards compliance – ensure it meets AS/NZS 3679.1 for structural steel.

- Supplier reliability – buy from local suppliers who provide test certificates and consistent quality.

Where to Buy Unequal Angle Steel in Perth

If you’re based in Western Australia and looking for quality unequal angle steel, choose a supplier that stocks a wide range of sizes, finishes, and grades ready for quick delivery. Many Perth-based steel distributors offer custom cutting, galvanising, and fabrication services, so you can get your materials tailored to your project’s exact needs.

Whether you’re building a new structure, reinforcing a frame, or designing a custom fabrication, unequal angle steel offers a dependable and efficient solution for modern construction.

You can find out more about us at our Fanpage Lintel Steel.