Steel C Section: 7 Key Tips to Choose the Right Pieces

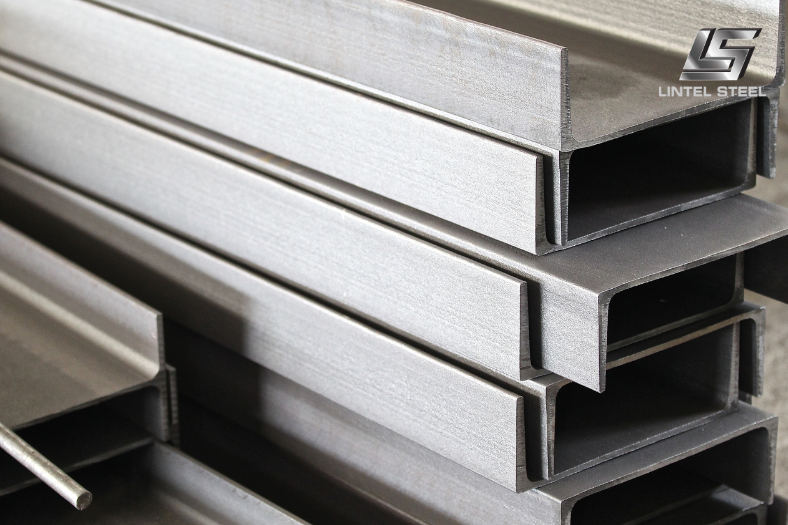

A steel C section is one of the most common shapes used in construction and metal building projects. Its “C” shape makes it strong, lightweight, and easy to work with, which is why it is often used for roof purlins, wall girts, frames, and many other structural parts. Steel C sections come in many sizes and thicknesses, making them suitable for both small jobs and large industrial projects.

Whether you are building a shed, a warehouse, or a steel-framed structure, choosing the right steel C section helps your project stay strong, stable, and long-lasting. In this article, we will explain what steel C sections are, how they are used, and how to choose the right one for your needs.

What Is a Steel C Section?

A steel C section, also known as a C-channel or C purlin, is a roll-formed or hot-rolled structural steel profile shaped like the letter “C.” It consists of a wide web and two parallel flanges, offering excellent strength-to-weight performance and high structural efficiency.

These sections are widely used in building frameworks, roofing systems, wall girts, and general fabrication because they combine lightweight construction with high load-bearing capability.

How Steel C Sections Are Manufactured

Steel C sections are produced using two main methods:

Roll-Formed C Sections

Made by feeding steel coil through a roll-forming machine to shape it into a C profile.

- Ideal for purlins, girts, lightweight framing.

- Offers high dimensional accuracy and consistent thickness.

- Common in galvanized steel for corrosion resistance.

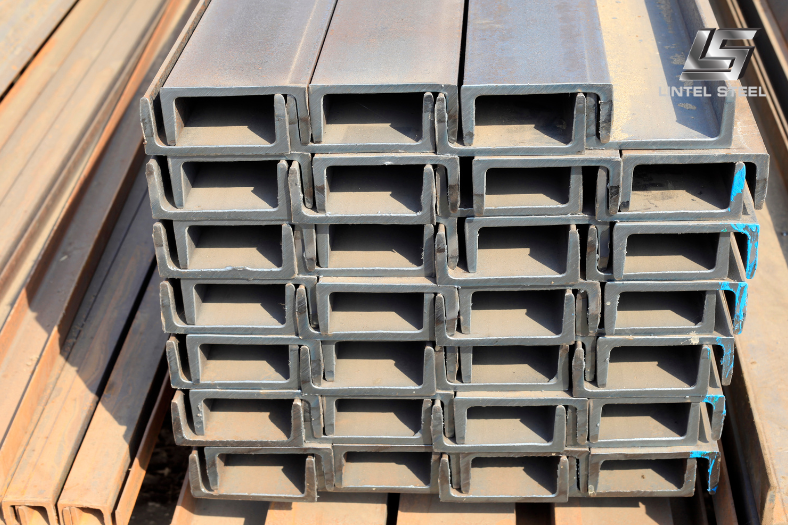

Hot-Rolled C Channels

Manufactured at high temperatures using traditional rolling mills.

- Heavier and stronger than roll-formed sections.

- Suitable for structural beams, columns, and industrial frames.

- Available in universal standard sizes (e.g., C100, C150, C200).

The manufacturing method affects strength, stiffness, thickness, and suitability for specific applications.

Key Features and Benefits of Steel C Sections

Steel C sections are popular because they offer a strong combination of performance and economy. Key advantages include:

- High Strength-to-Weight Ratio

C sections provide excellent structural efficiency while reducing overall material weight. This improves construction speed and reduces foundation loads. - Easy to Cut, Drill, and Install

Their straight profile and thin-gauge design (in roll-formed types) make installation fast and simple – ideal for rapid construction projects. - Versatile Applications

Suitable for use in walls, roof systems, mezzanines, trusses, and equipment framing. They are compatible with bolted, welded, or self-drilled connections. - Cost-Efficient

Because they use less material than solid beams or heavy channels, steel C sections offer significant cost savings without compromising strength. - Corrosion Resistance

Galvanised C sections are coated with zinc to prevent rusting, making them ideal for outdoor or coastal environments. - High Dimensional Precision

Roll-formed C sections are produced with tight tolerances, ensuring consistent performance and accurate alignment during installation.

Common Applications of Steel C Sections

Steel C sections support a wide range of construction and engineering uses, such as:

- Roof purlins and wall girts in steel buildings

- Portal frame structures and sheds

- Support systems for HVAC, piping, and conveyors

- Mezzanine floors and platforms

- Vehicle trailers and transport frames

- Residential and commercial light steel framing

- Bracing and structural reinforcement

Their adaptability allows engineers to use them in both load-bearing and bracing applications.

Understanding Steel C Section Sizes and Dimensions

The dimensions of a steel C section typically include:

- Depth (web height)

- Flange width

- Thickness (gauge or mm)

- Lip size (in lipped C purlins)

- Length (standard 6 m or custom-cut)

Common roll-formed C purlin sizes include:

- C75, C100, C150, C200, C250, C300

Hot-rolled channel sizes are often provided in:

- C100×50, C150×75, C200×75, C250×80, etc.

Choosing the correct dimension depends on span length, load type, spacing, and environmental conditions.

How to Choose the Right Steel C Section

Choosing the right steel C section is important because it affects how strong, safe, and stable your structure will be. Even though C sections are used in many projects, each size and thickness is designed for a different purpose. Here are the main things you should think about when picking the right one:

1. How Much Weight It Needs to Carry

Every project has different loads — for example, the weight of the roof, walls, equipment, or wind pressure.

- Heavier loads need larger and thicker C sections.

- Light loads can use small and thin sections.

Always choose a size that can safely support the load without bending.

2. How Long the Span Is

The span is the distance between two support points.

- A longer span needs a deeper and stronger C section.

- A shorter span can use smaller sections.

This helps prevent sagging or vibration in the structure.

3. Where the C Section Will Be Used

Think about the type of project:

- Roof purlins

- Wall girts

- Shed frames

- Mezzanine floors

Different areas need different strengths and stiffness, so match the section size to the job.

4. Environmental Conditions

Where the steel will be installed matters:

- Indoor projects can use normal black steel.

- Outdoor projects should use galvanised steel to prevent rust.

- Coastal or industrial areas may need heavier zinc coating or special finishes for long-term protection.

5. How You Plan to Connect It

The connection method affects which C section is suitable:

- Bolting requires pre-punched holes.

- Screwing needs thin-gauge, roll-formed C sections.

- Welding is easier with thicker hot-rolled channels.

Choosing a section that matches your connection method saves time during installation.

6. Standard Sizes vs. Custom Sizes

Many projects work well with standard C section sizes (such as C100, C150, C200). But some jobs need custom cuts, special lengths, or specific hole positions. Knowing what your project needs helps prevent delays.

7. Following Building Standards

Make sure the steel you choose meets the correct building standards such as AS/NZS, ASTM, or EN.

This ensures the C section is safe, strong, and approved for structural use.

Choosing the right steel C section helps your project stay safe, stable, and long-lasting. When in doubt, talk with your steel supplier or structural designer to pick a size that matches both your load requirements and your installation method.

Steel C Section Supplier in Perth – Lintel Steel

At Lintel Steel, we supply a full range of steel C sections, including galvanised C purlins, hot-rolled channels, and custom-cut profiles. With over 11 years of experience in steel supply and fabrication, our team ensures every section meets Australian Standards and project requirements.

We provide:

- Custom lengths and hole punching

- Galvanised or black steel options

- Fast delivery anywhere in Perth

- Free quotes within 48 hours

Whether you’re building a workshop, shed, mezzanine, or industrial structure, Lintel Steel delivers quality and reliability you can trust.

Conclusion

A steel C section is a highly efficient, versatile, and cost-effective structural component used across commercial, industrial, and residential construction. With strong load-bearing capabilities, lightweight design, and multiple size options, C sections are essential for modern building systems that require strength, speed, and precision.

Click here to get a quote and quantity takeoff for free.

You can find out more about us at our Fanpage Lintel Steel.