Stainless Steel Welder: 5 Common Welding Techniques

Stainless steel is one of the most durable and versatile materials used across industries — from construction and architecture to food processing, marine engineering, and medical manufacturing. But working with stainless steel requires more than just basic welding skills. It demands precision, control, and a deep understanding of metallurgy — qualities only a skilled stainless steel welder can provide.

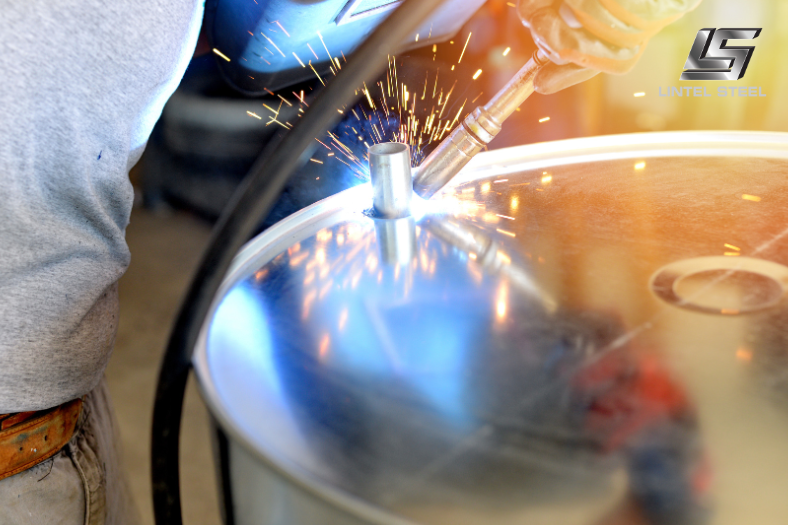

A stainless steel welder specializes in joining stainless steel components using advanced techniques such as TIG, MIG, or stick welding. Their role is critical in ensuring the final product is strong, corrosion-resistant, and visually flawless. Whether it’s fabricating custom handrails, repairing industrial tanks, or constructing hygienic equipment for commercial kitchens, stainless steel welders combine craftsmanship and technical knowledge to deliver results that meet the highest standards of quality and performance.

In this article, we’ll explore what a stainless steel welder does, the techniques they use, why stainless steel welding requires expertise, and how professional welding ensures long-lasting results for every project.

1. What Is a Stainless Steel Welder?

A stainless steel welder is a skilled tradesperson or automated welding specialist who joins stainless steel components using processes such as TIG, MIG, or stick welding. Unlike mild steel welding, stainless steel welding requires greater precision to maintain the metal’s corrosion resistance and surface finish.

Stainless steel welders work across multiple industries — from construction and architecture to food processing, marine, and medical equipment manufacturing. Their main goal is to produce clean, strong welds that can withstand demanding environments where hygiene, durability, and appearance are critical.

2. Stainless Steel Welding Techniques

A stainless steel welder must master several welding methods to achieve durable, clean, and corrosion-resistant joints. Each technique offers distinct advantages depending on the application, material thickness, and desired finish.

TIG (Tungsten Inert Gas) Welding

TIG welding is often considered the most precise and high-quality method for joining stainless steel. It uses a non-consumable tungsten electrode and an inert shielding gas, typically argon or helium, to protect the weld pool from contamination.

A skilled stainless steel welder can achieve smooth, aesthetically pleasing welds with excellent control over penetration and bead appearance. This technique is ideal for thin sheets, food-grade equipment, and architectural components where appearance and hygiene are crucial. TIG welding also minimizes distortion and spatter, maintaining the metal’s clean finish and corrosion resistance.

MIG (Metal Inert Gas) Welding

MIG welding is known for its speed and efficiency. It employs a consumable wire electrode that feeds continuously through a welding gun, making it suitable for thicker stainless sections and high-volume production.

A stainless steel welder using MIG can create strong joints quickly with less operator fatigue, making it a preferred choice for structural fabrication, automotive parts, and industrial equipment. However, achieving a clean surface requires careful shielding gas selection and consistent travel speed to prevent oxidation and spatter.

Stick Welding (SMAW)

Stick welding is one of the oldest and most versatile stainless steel welding techniques. It’s particularly useful for outdoor and field applications because it doesn’t rely heavily on shielding gas, which can be affected by wind.

Stainless steel welders often use special low-hydrogen electrodes to ensure crack resistance and consistent arc stability. While this method may produce more slag and require cleanup, it delivers reliable, durable welds in construction, maintenance, and repair projects where portability is key.

Spot Welding (Resistance Welding)

Spot welding joins stainless steel sheets by applying heat and pressure at localized points. It’s fast, efficient, and ideal for mass production — commonly used in the automotive, appliance, and electronics industries.

A stainless steel welder performing spot welding must balance current, pressure, and weld time precisely to prevent overheating or warping, ensuring clean, uniform joints without compromising corrosion resistance.

Laser and Plasma Welding

In advanced fabrication environments, stainless steel welders may also work with laser or plasma welding systems. These methods provide exceptional precision and minimal heat-affected zones, allowing for intricate designs and thin-gauge materials. Laser welding is especially valuable in aerospace, medical device, and high-end manufacturing applications where precision and consistency are critical.

3. Why Stainless Steel Welding Requires Expertise

Welding stainless steel is not the same as welding mild or carbon steel. The properties that make stainless steel so durable and corrosion-resistant also make it more challenging to work with. A skilled stainless steel welder must understand the unique behavior of this metal under heat and stress, and apply precise techniques to achieve high-quality results.

The Challenges of Stainless Steel Welding

Stainless steel contains chromium, nickel, and other alloying elements that give it strength and corrosion resistance. However, these same elements react differently when exposed to high heat, leading to potential problems such as:

- Warping and distortion: Stainless steel expands and contracts more than carbon steel when heated, causing parts to bend or lose alignment if not properly managed.

- Discoloration or oxidation: Excessive heat or improper shielding gas can leave unattractive brown or blue marks, compromising both appearance and corrosion resistance.

- Carbide precipitation: Overheating can cause chromium to bond with carbon, reducing the material’s ability to resist rust and corrosion.

- Contamination risks: Even small traces of dirt, oil, or carbon steel particles on tools can react with stainless steel, leading to rust spots and weakened joints.

- Heat-affected zones (HAZ): Poor control of temperature can create weak points near the weld area, affecting long-term durability.

Because of these challenges, stainless steel welding demands more than just standard welding skill — it requires knowledge, preparation, and attention to microscopic details.

What a Professional Stainless Steel Welder Does Differently

An experienced stainless steel welder uses advanced techniques and best practices to ensure the weld’s strength and appearance meet strict quality standards. Their expertise includes:

- Controlling heat input: Maintaining a consistent temperature to avoid distortion and preserve mechanical properties.

- Using the right filler materials: Matching filler rods or wires to the stainless grade to prevent galvanic corrosion and ensure seamless bonding.

- Selecting proper shielding gas: Using argon or helium-based mixtures to protect the weld pool from oxygen contamination.

- Cleaning and preparation: Ensuring the metal surface is free from dust, oil, and ferrous particles before welding begins.

- Post-weld treatment: Applying passivation or polishing to restore the natural protective chromium oxide layer for long-term corrosion resistance.

- Precision in joint design: Choosing joint types and fit-ups that minimize heat buildup and allow smooth, even penetration.

Why Expertise Matters

A professional stainless steel welder doesn’t just join two pieces of metal — they preserve the material’s structural integrity and aesthetic value. Mistakes during welding can lead to costly repairs, premature corrosion, or even safety failures in structural applications.

By combining technical skill, material knowledge, and meticulous workmanship, a qualified welder ensures that every stainless steel project — whether it’s architectural framing, food-grade equipment, or marine fabrication — remains strong, clean, and built to last.

4. Key Benefits of Hiring a Professional Stainless Steel Welder

Working with a qualified stainless steel welder ensures:

- Superior corrosion resistance: Correct welding techniques preserve stainless steel’s protective chromium oxide layer.

- Enhanced durability: Professional welds deliver long-lasting structural strength.

- Clean, aesthetic finishes: Perfect for architectural or visible components.

- Compliance with standards: Certified welders adhere to industry and safety codes.

Whether it’s for custom fabrication, repair, or large-scale industrial production, choosing a professional welder guarantees quality and consistency.

5. Applications of Stainless Steel Welding

Stainless steel welding is used in a wide range of sectors, including:

- Building and architectural frameworks

- Handrails, balustrades, and structural supports

- Food-grade and pharmaceutical equipment

- Marine structures and transport components

- Energy, petrochemical, and water treatment facilities

In every field, stainless steel welders play a vital role in ensuring safety, hygiene, and strength.

6. Final Thoughts

A skilled stainless steel welder combines technical knowledge, precision, and craftsmanship to create joints that are as strong and resilient as the metal itself. Whether you need fabrication, installation, or repair, working with experts ensures your stainless steel projects meet the highest standards of performance and finish.

You can find out more about us at our Fanpage Lintel Steel.