Stainless Steel Angle: 6 Points to Choose the Right Angle

When strength meets precision, stainless steel angle becomes an essential component in both structural and aesthetic design. Its uniform “L” profile provides exceptional load-bearing capacity, while the stainless composition ensures long-term corrosion resistance — even in harsh or marine environments. Available in a wide range of sizes, finishes, and grades like 304 and 316, stainless steel angle remains a preferred choice for engineers seeking reliable performance with minimal maintenance.

Let’s take a closer look at what makes it so essential, the types available, common sizes, and why stainless steel is preferred over other materials.

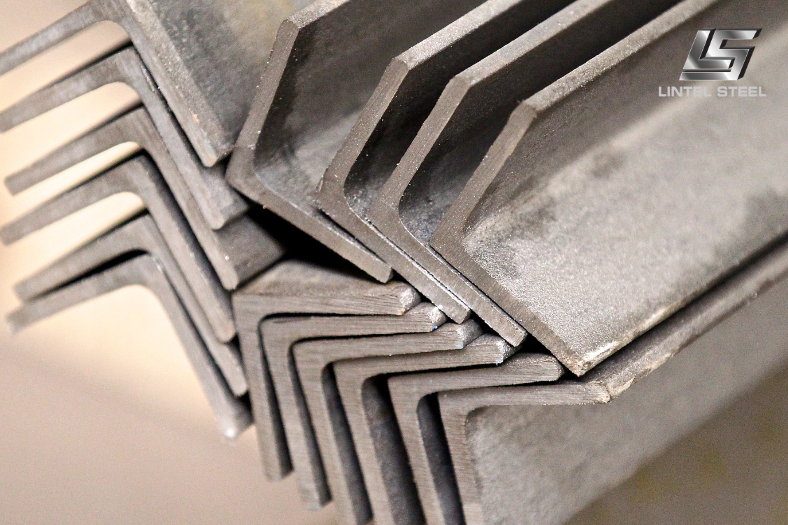

What Is a Stainless Steel Angle?

A stainless steel angle is a long piece of steel shaped like the letter “L,” with two sides — or legs — that meet at a right angle. These legs can be equal or unequal in length, depending on the application.

It’s typically made from high-grade stainless steel such as 304 or 316, which are known for their resistance to corrosion and heat. These qualities make it ideal for both indoor and outdoor projects, especially in environments exposed to moisture, salt air, or chemicals — like coastal areas or industrial plants.

The stainless steel angle is often used for frameworks, brackets, shelves, supports, and trims. Its simplicity hides its power — it’s one of the most adaptable materials in any metal workshop.

Common Stainless Steel Angle Sizes

The size of a stainless steel angle can vary widely depending on its intended use. Common options include:

- 25 x 25 x 3 mm – lightweight frames, brackets, or interior trims

- 40 x 40 x 5 mm – shelving, furniture, or light construction

- 50 x 50 x 6 mm – machinery frames or warehouse installations

- 75 x 75 x 6 mm – structural reinforcement or external support frames

- 100 x 100 x 8 mm – heavy-duty construction and industrial frameworks

Standard lengths are usually 6 metres, but they can be custom-cut to fit specific projects.

For marine or chemical exposure, 316 stainless steel angle is recommended, while 304 is a great all-purpose option for most construction and fabrication uses.

Why Use Stainless Steel Angle?

- Corrosion Resistance

Unlike mild or carbon steel, stainless steel angle resists rust even when exposed to water or humid air. This makes it ideal for outdoor or coastal structures, where longevity matters most. - High Strength-to-Weight Ratio

Stainless steel offers excellent strength without excessive weight. It provides rigidity and stability while being easy to handle and install. - Hygienic and Easy to Clean

Stainless steel’s smooth surface resists bacteria buildup and staining — a must for food processing, medical, or cleanroom environments. - Aesthetic Appeal

The polished, reflective surface of stainless steel angle adds a modern and professional finish, making it popular in architectural or interior applications. - Low Maintenance and Long Lifespan

Once installed, it requires minimal upkeep, saving time and money over decades of use.

Stainless Steel Angle Applications

Because of its strength and clean finish, stainless steel angle is found in a wide range of industries and projects:

- Construction – reinforcement, support structures, roofing edges, and cladding

- Marine – boat frames, docks, and coastal architectural elements

- Manufacturing – machine guards, brackets, and frame assembly

- Food and Beverage – equipment frames, benches, and racks

- Interior Design – stair edges, decorative trims, and shelving

- Infrastructure – walkways, platforms, and safety rails

In every case, it provides a strong and corrosion-proof backbone for both functionality and style.

Stainless Steel Angle vs. Mild Steel Angle

While both serve similar structural purposes, the difference lies in durability and environment. Mild steel is cheaper but prone to corrosion unless coated or galvanized. Stainless steel angle, on the other hand, is naturally resistant to rust — no need for extra coatings or frequent repainting.

In the long term, stainless steel often proves more cost-effective, especially in harsh or exposed environments where mild steel would require ongoing maintenance or replacement.

How to Choose the Right Stainless Steel Angle

Selecting the correct stainless steel angle for your project requires a thoughtful look at both performance needs and environmental factors. While all stainless steel angles share strength and corrosion resistance, subtle differences in grade, thickness, and finish can significantly impact cost, durability, and visual results.

Here are the key factors to consider before you buy:

1. Environment and Corrosion Exposure

Your project’s location and surrounding environment are the first things to assess.

- For marine, coastal, or chemical environments, the 316 stainless steel angle is the best choice. It contains molybdenum, which enhances resistance to chloride and salt corrosion — perfect for seaside homes, docks, and industrial sites.

- For indoor or dry applications, 304 stainless steel angle is usually sufficient. It offers excellent corrosion resistance for structures like frames, furniture, or architectural trims where exposure to harsh elements is limited.

Tip: If your installation is near swimming pools, coastal air, or chemical plants, always go with 316. The small price difference pays off by preventing pitting or rust in the long run.

2. Load Requirements and Structural Demands

Think about how much load or pressure the angle will support. The thickness and leg size directly affect how much weight it can handle.

- Light-duty applications (shelves, racks, or interior trim) can use smaller sizes like 25 x 25 x 3 mm or 40 x 40 x 5 mm.

- Medium-duty applications (machine frames, equipment mounts, partitions) may require 50 x 50 x 6 mm or 65 x 65 x 6 mm.

- Heavy-duty or structural frameworks (platforms, stairs, or exterior supports) often call for 75 x 75 x 8 mm or 100 x 100 x 10 mm profiles.

If your project involves vibration, load-bearing, or structural bracing, always consult your engineer or supplier for load charts and safe weight limits.

3. Finish and Appearance

The surface finish of a stainless steel angle affects not only how it looks but also how it performs in certain environments.

- Mill finish (raw from the mill) – economical and ideal for hidden structural use.

- Brushed finish (satin) – popular for visible surfaces like benches, shopfittings, or architectural trims, offering a smooth matte look.

- Mirror finish – highly polished, reflective, and resistant to staining; perfect for decorative or hygiene-sensitive applications such as hospitals, commercial kitchens, and showrooms.

A polished finish also makes cleaning easier, reducing dirt buildup and improving corrosion resistance.

4. Dimensions and Custom Cutting

Stainless steel angles are typically supplied in 6-metre lengths, but most suppliers offer custom cutting services to match your project size exactly. This not only saves time during installation but also reduces waste.

When specifying, consider:

- The leg length (height of each side of the “L”)

- The thickness (how sturdy or flexible the angle will be)

- The angle precision (sharp corner vs. rounded edge)

If you’re building modular systems, request precision-cut and deburred edges to ensure a clean fit and professional finish.

5. Fabrication and Welding Compatibility

Some projects require the stainless steel angle to be cut, welded, or drilled during fabrication. Grades 304 and 316 are both easy to weld and machine, but 316 offers superior weld corrosion resistance — ideal for long-lasting outdoor or marine welds.

If you plan to weld, make sure to use stainless-compatible filler rods and to clean the welded areas afterward to restore corrosion protection.

6. Budget and Lifecycle Cost

Although stainless steel angle costs more upfront than mild steel, its longer lifespan often makes it the smarter financial choice. It eliminates the need for frequent repainting, galvanizing, or replacement due to rust.

Think of it as an investment: a one-time cost for decades of performance and visual appeal.

By evaluating these factors — environment, load, finish, dimensions, fabrication, and cost — you can choose the stainless steel angle that delivers both strength and style, without unnecessary expense or maintenance headaches.

In short: the right selection ensures your structure stays safe, corrosion-free, and visually impressive for years to come.

Where to Buy Stainless Steel Angle in Perth

For builders, fabricators, or DIY enthusiasts in Perth, finding a reliable stainless steel angle supplier is crucial. Look for local suppliers offering Australian Standard-certified stainless steel, custom cutting, and quick delivery.

Working with a local Perth steel supplier ensures you get materials suited for the local climate, including coastal corrosion resistance and structural compliance. Some even provide fabrication services — helping you get custom-cut angles ready for installation.

Final Thoughts

The stainless steel angle might seem like a simple piece of metal, but it plays a vital role in modern design and construction. Its combination of strength, resilience, and visual appeal makes it a timeless choice for countless projects.

Whether you’re building, fabricating, or designing, stainless steel angle offers a material that’s built to last, built to perform, and built to impress.

You can find out more about us at our Fanpage Lintel Steel.