Square Hollow Section (SHS) & 5 Key Advantages You Should Know

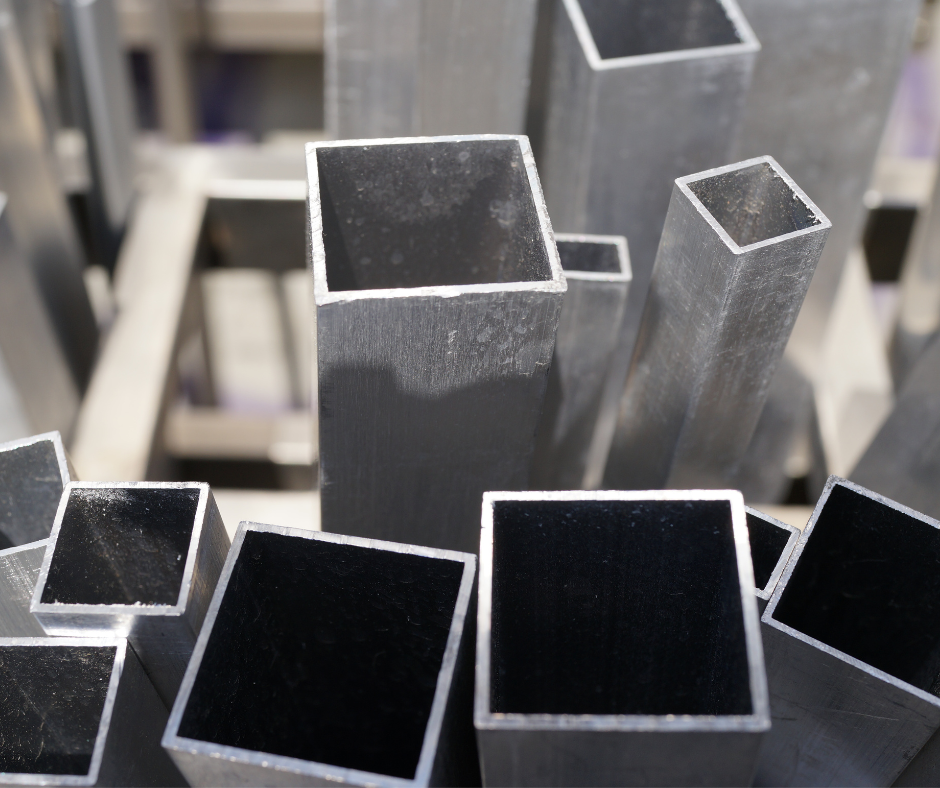

The square hollow section (SHS) is a highly versatile and widely used steel profile in modern construction, manufacturing, and engineering. Recognised for its clean lines, uniform shape, and exceptional structural performance, the square hollow section offers a perfect balance of strength, durability, and aesthetic appeal. Whether it’s used for building frameworks, architectural features, or machinery components, this type of steel tubing delivers reliability and efficiency in a wide range of applications.

Available in various sizes, thicknesses, and finishes, the square hollow section can be customised to meet the demands of different projects. Its closed shape provides excellent resistance to torsion, making it a preferred choice for load-bearing structures, while its sleek appearance makes it equally suitable for visible installations. From large-scale industrial projects to small DIY builds, the SHS continues to be a go-to material for professionals and hobbyists alike.

What is a Square Hollow Section?

A square hollow section (SHS) is a type of structural steel tube with a square cross-section and hollow interior. Known for its clean lines, uniform strength, and excellent load-bearing capacity, the square hollow section is widely used in construction, engineering, and manufacturing. Its precise dimensions and smooth finish make it an ideal choice for both functional frameworks and architectural designs.

Key Advantages of Square Hollow Section

1. High Structural Strength

The geometry of the square hollow section distributes weight evenly across all four sides, giving it excellent resistance to bending, compression, and torsion. This makes it a preferred material for load-bearing structures, bridges, and heavy-duty frameworks.

2. Versatile Design Options

A square hollow section can be used in everything from building columns and support beams to furniture frames and industrial equipment. Its sharp, modern profile also makes it popular in visible applications where aesthetics matter.

3. Lightweight Yet Durable

Compared to solid steel bars, the square hollow section delivers similar strength with reduced weight. This allows for easier transportation, faster installation, and cost savings without compromising durability.

4. Excellent Weldability and Fabrication

The smooth surface and uniform wall thickness of the square hollow section make it easy to cut, drill, and weld. Fabricators can adapt it for custom designs, from curved architectural features to precision-engineered components.

5. Cost-Effective and Low Maintenance

Whether galvanised, painted, or left untreated, a square hollow section requires minimal maintenance. Its durability reduces the need for frequent repairs or replacements, saving both time and money over the structure’s lifespan.

Common Applications of Square Hollow Section

Construction & Infrastructure

Square hollow section (SHS) is a go-to choice for structural elements such as columns, rafters, trusses, and building frameworks. Its uniform geometry and high load-bearing capacity make it ideal for both commercial and residential projects. From supporting multi-storey buildings to creating durable roofing frameworks, SHS ensures strength without adding unnecessary bulk.

Industrial Manufacturing

In manufacturing environments, square hollow section is frequently used to build machinery frames, conveyor supports, storage racks, and custom equipment structures. The smooth surfaces and even wall thickness allow for easy fabrication, cutting, and welding, making SHS a time-saving and cost-effective option for production lines and heavy-duty setups.

Furniture & Interior Design

Designers and fabricators often choose SHS for contemporary furniture such as tables, chairs, shelving units, and modern partitions. Its clean, square edges and versatility enable both functional and decorative use. SHS can be powder-coated, polished, or painted to match any interior aesthetic while maintaining a solid and long-lasting frame.

Agriculture

Farmers and agricultural businesses rely on SHS to build greenhouse frames, sturdy gates, livestock pens, and fencing posts. The material’s durability, especially when galvanised, ensures resistance to weather, moisture, and corrosion — a critical advantage in outdoor and high-humidity environments.

Transport & Logistics

In the transport sector, square hollow section is widely used for manufacturing trailers, transport containers, pallet frames, and material handling equipment. The strength-to-weight ratio of SHS means these structures can handle heavy loads while staying relatively lightweight, which improves fuel efficiency and ease of movement.

Finishes and Treatments for SHS

One of the advantages of using a square hollow section is the variety of finishes and surface treatments available. These finishes not only enhance the material’s appearance but also improve its performance, lifespan, and suitability for specific environments. Choosing the right finish depends on factors such as location, weather exposure, desired aesthetics, and budget.

- Galvanised SHS

Galvanised square hollow section is treated with a protective zinc coating through hot-dip galvanising or electro-galvanising. This layer of zinc acts as a barrier against moisture, oxygen, and other corrosive elements, making it the preferred choice for outdoor structures, coastal regions, and industrial environments where rust prevention is critical. Galvanised SHS is commonly used for fencing, gates, outdoor furniture frames, and building frameworks that must withstand harsh weather conditions. - Painted or Powder-Coated SHS

Painting or powder-coating a square hollow section adds both aesthetic appeal and extra protection. Powder coating involves applying a dry powder that is cured under heat, forming a tough, uniform finish that resists chipping, scratching, and fading. These finishes are available in a wide range of colours, making them ideal for projects where visual appearance is important, such as architectural facades, interior furniture, and decorative railings. In addition, paint and powder coatings provide a layer of corrosion resistance, extending the life of the steel. - Mill Finish SHS

Mill finish square hollow section is supplied in its raw, untreated state directly from the manufacturing process. This option is suitable for indoor use, projects where the SHS will be painted or coated later, or applications where surface protection is not a priority. Mill finish SHS offers flexibility for custom finishing and is often chosen by fabricators who want complete control over the end look and performance of the material. - Specialised Coatings and Treatments

In addition to the standard options, some projects require more advanced finishes for specific performance requirements. These include epoxy coatings for chemical resistance, fire-resistant paints for safety compliance, and duplex coatings that combine galvanising with powder coating for maximum protection. Specialised treatments ensure that the square hollow section can perform reliably even in highly demanding or corrosive environments such as chemical plants, marine applications, and extreme climates.

Why Choose the Square Hollow Section for Your Project?

The square hollow section is one of the most reliable and adaptable steel profiles used across multiple industries. Its uniform shape delivers exceptional load-bearing capacity, making it ideal for applications where both strength and balance are essential. Thanks to its closed-tube design, a square hollow section resists torsion and buckling better than many open profiles, ensuring stability and durability even under heavy stress.

Beyond its strength, the square hollow section is also valued for its clean, modern aesthetic. Its straight edges and smooth surfaces create a contemporary look that fits seamlessly into architectural designs, while also allowing for easier cladding, painting, or powder coating. This makes it equally suitable for visible structural features and hidden framework.

From large-scale commercial construction to precision manufacturing and home DIY projects, a square hollow section offers versatility that few materials can match. It can be welded, cut, drilled, and shaped to suit your specific requirements, providing a balance of performance and cost-efficiency. When your project demands a steel profile that combines durability, design flexibility, and long-term value, the square hollow section remains one of the best choices available.

You can find out more about us at our Fanpage Lintel Steel.