SHS vs RHS: 7 Key Differences to Pick the Right Steel for Your Project

When it comes to structural steel, both SHS (Square Hollow Section) and RHS (Rectangular Hollow Section) are incredibly popular choices. They are used in residential, commercial, and industrial projects across Australia and the world. But how do they compare? In this guide, we’ll walk you through the key differences, benefits, and best use cases for SHS vs RHS, so you can make the right decision for your build.

What Are SHS and RHS?

Before comparing SHS vs RHS, let’s define each one:

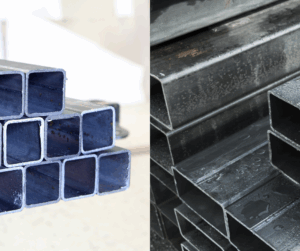

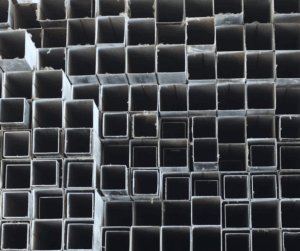

SHS – Square Hollow Section

SHS stands for Square Hollow Section. As the name suggests, this type of steel has a square cross-section. Common dimensions include 50x50mm, 100x100mm, and 150x150mm, with wall thicknesses ranging from 1.6mm to over 10mm.

SHS is known for:

- Uniform strength in both directions

- Symmetry, making it ideal for visible or architectural applications

- Ease of connection in structural frames

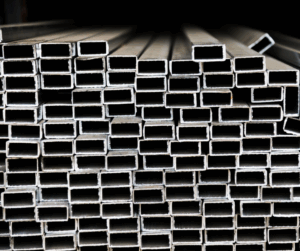

RHS – Rectangular Hollow Section

RHS stands for Rectangular Hollow Section. These steel tubes have a rectangular profile and are often used in applications requiring greater load-bearing in one direction.

Key traits of RHS include:

- Higher moment of inertia in one axis

- Wider range of sizes, such as 50x100mm, 150x100mm, etc.

- Efficient for beams and horizontal supports

SHS vs RHS: Key Differences

Let’s dive deeper into how SHS vs RHS compare across important factors:

1. Shape and Geometry

- SHS: Equal width and height (e.g., 100mm x 100mm)

- RHS: Unequal width and height (e.g., 100mm x 50mm)

The difference in geometry affects how the load is distributed. SHS offers balanced support in both directions, while RHS is stronger in one direction.

2. Load Distribution

- SHS: Excellent for compression or load from multiple directions. Ideal for columns and upright structures.

- RHS: Better for bending and flexural strength in one direction, making it ideal for horizontal beams, trusses, and lintels.

3. Aesthetic Appearance

If the steel is exposed, SHS often provides a cleaner, more symmetrical look. It’s frequently used in architectural finishes, handrails, and visible posts.

4. Weight and Material Efficiency

- RHS can be more material-efficient when spanning long distances horizontally.

- SHS may weigh more for the same wall thickness, due to equal width-height.

This can affect transport, cost, and installation time.

5. Connection and Welding

- SHS offers easier connection symmetry, especially for joints at 90° angles.

- RHS connections may need more customization, but are still structurally sound when properly welded or bolted.

SHS vs RHS: Common Applications

Here’s a side-by-side look at where each section performs best:

| Application Type | SHS Steel | RHS Steel |

| Structural Columns | Excellent | Acceptable |

| Roof Trusses | Moderate | Excellent |

| Beams & Purlins | Okay | Best |

| Balustrades & Handrails | Great visual finish | Acceptable |

| Fencing & Gates | Clean lines | Strong and durable |

| Frames & Supports | Balanced loads | Directional strength |

| Furniture & Fabrication | Lightweight and symmetrical | Sleek and strong |

Cost Comparison: Is SHS or RHS Cheaper?

Price can vary based on:

- Size and wall thickness

- Steel grade and coating (galvanized or raw)

- Cutting and fabrication needs

Generally, RHS may be slightly cheaper per linear metre, especially for larger spans where it provides the required strength with less material. However, SHS is often more versatile in general-purpose builds.

When comparing SHS vs RHS cost-effectiveness, always consider the total installed cost, not just the raw material price.

SHS vs RHS in Australian Standards

Both SHS and RHS are manufactured to strict standards such as AS/NZS 1163 for structural steel. This ensures:

- Consistent wall thickness

- Accurate dimensions and squareness

- Smooth weld seams

- Reliable structural performance

Look for these markings when purchasing steel from an Australian supplier.

Pros and Cons Summary

Here’s a quick overview of the pros and cons of SHS vs RHS:

SHS Steel: Pros

- Balanced strength

- Aesthetic symmetry

- Easier to connect at right angles

- Common sizes available

SHS Steel: Cons

- Slightly heavier per meter

- May be overkill for directional loads

RHS Steel: Pros

- Excellent flexural strength in one direction

- More efficient material use for beams

- Often lower cost for same span

RHS Steel: Cons

- Asymmetrical appearance

- Slightly more complex connections

How to Choose Between SHS and RHS

Selecting between SHS vs RHS isn’t always straightforward, especially if you’re planning a project that demands both structural strength and visual appeal. Each section has distinct advantages, so it’s important to evaluate your specific needs before deciding. Here are the key factors to consider:

1. Define the Structural Role of the Steel Section

Start by identifying what the steel member will actually do in your structure. Is it acting as a vertical column, a horizontal beam, a brace, or simply a decorative element?

- SHS is ideal for columns and vertical posts, thanks to its uniform load resistance in both horizontal and vertical directions. Its symmetrical shape also gives it great aesthetic value when visible in the design.

- RHS is often used for beams, rafters, purlins, and trusses, especially in situations where strength is primarily needed in one direction. Its shape gives it a higher moment of inertia, which means it’s better at resisting bending forces in a specific plane.

2. Understand the Load Direction and Force Distribution

Next, ask yourself: Where is the force coming from?

- SHS distributes loads evenly in all directions due to its square geometry. This is especially important when the load isn’t predictable or comes from various angles (e.g. wind, multi-floor structures).

- RHS, on the other hand, is excellent for resisting loads that are clearly directional—such as in roof frames or floor supports where the force is downward or upward along one plane.

For example, if you’re designing a gate post that may be pushed or pulled from multiple angles, SHS will give you the best stability. But if you’re building a canopy beam with downward pressure only, RHS might be more efficient.

3. Calculate the Required Span and Support Gaps

If your project involves spanning long distances, such as roof trusses or horizontal bridges between supports, then RHS often performs better due to its ability to bear heavier loads over wider gaps.

- RHS can achieve longer spans without sagging or flexing, making it popular for shed roofs, pergolas, and warehouse beams.

- SHS is also structurally sound but may require closer support points or thicker walls to achieve the same results.

Always balance span length with wall thickness, weight, and material costs. Overspecifying adds cost, while underspecifying risks failure.

4. Consider the Final Appearance and Design Goals

Aesthetics matter—especially in architectural steelwork, such as fences, facades, or exposed framing.

- SHS offers a clean, symmetrical appearance, which many designers prefer for visible applications. Its even edges, square look, and balanced proportions create a professional, polished finish.

- RHS looks more industrial and may appear bulky if used upright. However, it’s still widely used in fabrication and modern architecture, especially when laid flat or embedded within walls.

So if visual harmony is important—such as in balustrades, staircases, furniture, or modern facades—SHS might be the better choice. If the section will be hidden or integrated within other materials, RHS could save weight and money.

5. Think About Fabrication, Welding, and Connection Simplicity

SHS sections tend to be easier to work with, especially when it comes to 90-degree joints or uniform cuts, because all sides are equal.

- SHS simplifies joint fabrication in modular frames or welded assemblies.

- RHS may require more careful planning for weld angles and lengths due to its rectangular shape, particularly in complex junctions.

If you’re working on a DIY project or planning to fabricate many identical units, SHS may reduce waste and time.

6. Review Available Sizes and Wall Thickness Options

Before making a final decision, check the availability of each section in your region. Most Australian suppliers stock a wide range of SHS vs RHS steel, but specific dimensions may vary.

- SHS is commonly available in sizes like 50x50mm, 100x100mm, up to 200x200mm.

- RHS offers more flexible sizing—e.g., 50x25mm, 100x50mm, 150x100mm, allowing for finer load control.

Matching the steel dimensions to your design is essential for structural safety and economic efficiency.

7. Consult a Structural Engineer for Expert Advice

Finally, for any large-scale, multi-storey, or safety-critical structure, it’s best to consult a qualified structural engineer. They can provide:

- Accurate load calculations

- Steel section sizing based on stress and moment distribution

- Compliance with AS/NZS 1163 and local building codes

- Recommendations based on real-world performance, not just theory

Getting professional advice at the start can save significant time and cost down the line—and ensure safety across the board.

Final Thoughts on SHS vs RHS

Both SHS and RHS offer unique strengths. SHS shines in balanced and symmetrical loads, while RHS is ideal for directional strength and efficient spanning. The right choice depends on your specific needs—structural, aesthetic, and budget.

If you’re still unsure about SHS vs RHS, our steel experts are here to help.

Need help choosing the right steel section?

Get a fast, free quote today—just send us your specs or drawings. We’ll recommend the best SHS or RHS option based on your build.

You can find out more about us at our Fanpage Lintel Steel.