RHS Sizes: Top 5 Ways to Find The Right RHS Sizes

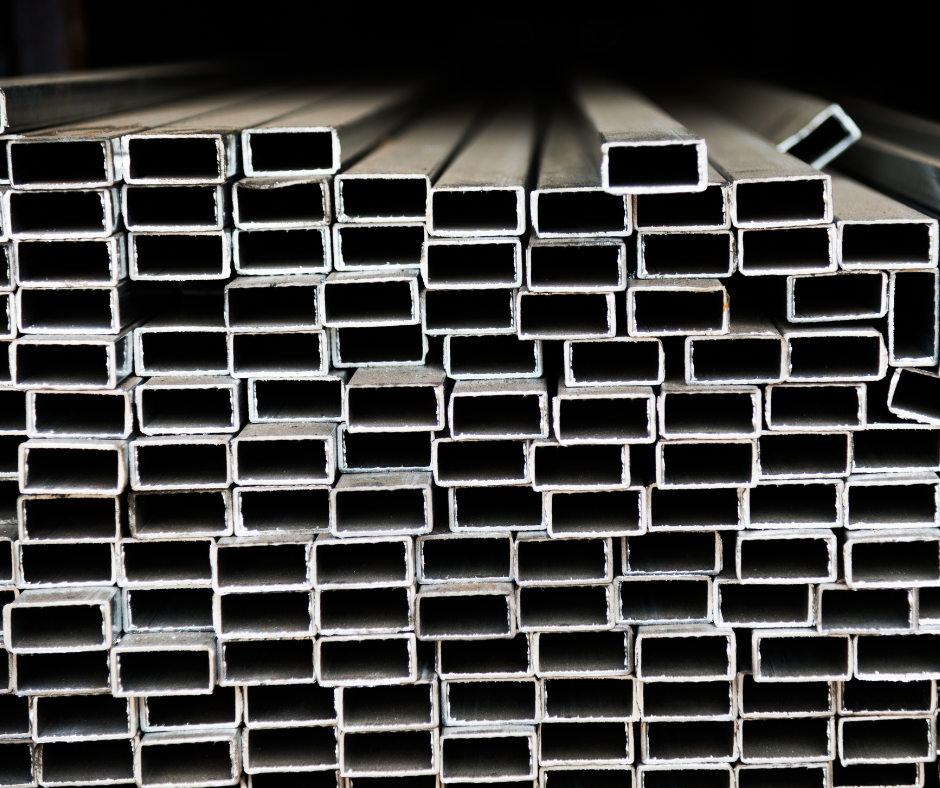

If you’re working on a construction or engineering project, understanding RHS sizes is essential. Rectangular Hollow Sections (RHS) are one of the most versatile steel profiles used in Australia and worldwide. With their flat surfaces and excellent load-bearing capacity, RHS steel tubes are ideal for structural, architectural, and mechanical applications.

In this guide, we’ll walk you through what RHS sizes mean, how to read them, and how to choose the right size for your next project.

What Are RHS Sizes?

RHS stands for Rectangular Hollow Section, a type of steel tube with a rectangular cross-section. These sections are identified primarily by three dimensions:

- Height (H) – the longer outer side of the rectangle

- Width (W) – the shorter outer side

- Wall thickness (t) – the thickness of the steel walls

For example, an RHS labeled 100 x 50 x 3.0 mm has:

- 100 mm height

- 50 mm width

- 3.0 mm wall thickness

These dimensions directly influence the strength, weight, and cost of the steel section.

Why RHS Sizes Matter

Selecting the correct RHS size is critical for:

- Structural integrity: A size too small might not support the load.

- Material efficiency: Oversizing increases cost and weight unnecessarily.

- Fabrication: Some sizes are easier to cut, weld, or transport.

- Aesthetics: Especially important in architectural features.

Understanding standard RHS sizes gives you confidence in your design and helps streamline the procurement process.

Standard RHS Sizes in Australia

RHS steel is typically available in metric sizes. In Australia, suppliers stock a wide range of RHS sizes that comply with AS/NZS 1163 – the Australian standard for structural steel hollow sections.

Here are some commonly available RHS sizes:

| Height (mm) | Width (mm) | Wall Thickness (mm) | Approx. Weight (kg/m) |

| 50 | 25 | 2.0 | 2.46 |

| 75 | 50 | 3.0 | 6.16 |

| 100 | 50 | 3.0 | 7.31 |

| 150 | 100 | 5.0 | 21.20 |

| 200 | 100 | 6.0 | 28.20 |

Note: Dimensions and weights may vary slightly depending on the supplier or manufacturer. Always request a product specification sheet for exact details.

How to Read RHS Size Charts

When browsing RHS size tables, you’ll usually see data formatted as:

Height x Width x Thickness

For example:

- 100 x 50 x 2.5 = 100mm high, 50mm wide, 2.5mm wall thickness

- 150 x 100 x 6.0 = 150mm high, 100mm wide, 6.0mm wall thickness

Some charts may also include:

- Mass per meter (kg/m)

- Section properties such as Area, Second Moment of Area (I), Radius of Gyration, and Section Modulus

These properties are essential for structural engineers but can be simplified when you’re estimating weight or selecting materials for general fabrication.

Popular Applications Based on RHS Sizes

Different RHS sizes suit different types of jobs. Here’s a breakdown of typical applications:

1. Small RHS Sizes (e.g., 25×25 to 75×50 mm)

- Furniture frames

- Handrails and balustrades

- Lightweight bracing or supports

- Display racks

2. Medium RHS Sizes (e.g., 100×50 to 150×100 mm)

- Framing in residential and commercial buildings

- Vehicle trailers

- Gates and fencing

- Pergolas and patio supports

3. Large RHS Sizes (e.g., 200×100 mm and above)

- Load-bearing columns

- Structural beams

- Industrial sheds

- Heavy-duty racking and platforms

Choosing the right size isn’t just about what fits — it’s about what lasts, what performs, and what complies with standards.

How to Choose the Right RHS Size

Choosing the correct RHS size can make or break your project’s success. A poorly selected section may lead to structural failures, unnecessary costs, or even fabrication delays. To avoid costly mistakes, here’s a deeper look into the five key factors you should always consider when selecting the right Rectangular Hollow Section.

1. Define the Load Requirements in Detail

Start by asking: What kind of forces will act on the steel section?

- Static loads (e.g., a wall or roof) may require moderate sizes, but

- Dynamic or moving loads (like a vehicle ramp or vibrating equipment support) demand stronger, more durable sections.

Also, identify whether the loads are:

- Point loads (concentrated in one spot)

- Distributed loads (spread out evenly)

Both influence the choice of height, width, and wall thickness. Engineers often refer to load tables or structural software to ensure the selected RHS size meets required stress limits without buckling or sagging. The larger the span or higher the load, the larger and thicker the RHS needs to be.

2. Consider the Environmental Conditions

Where will the RHS be used — indoors or outdoors? In coastal or industrial areas?

Environmental exposure has a huge impact on material selection. For example:

- Indoor framing in dry conditions can use standard RHS with a primer coat.

- Outdoor applications like pergolas or posts near the ocean should use hot-dip galvanised or zinc-coated RHS to prevent rust and corrosion.

- Harsh industrial zones may require additional coatings or even stainless steel RHS.

By selecting the right surface treatment and size to suit the conditions, you extend the lifespan of your steel and reduce long-term maintenance costs.

3. Evaluate the Trade-Off Between Weight and Strength

It’s common to assume bigger is better — but that’s not always true. Bigger RHS sizes mean:

- More weight per meter, increasing shipping and handling costs

- Higher steel cost, especially with thick walls

Instead, consider optimizing the strength-to-weight ratio. Depending on your structural requirements, a smaller RHS with higher wall thickness might perform just as well as a large, thin-walled one — with less material waste.

Use structural performance tables to compare second moments of area (I) and section modulus (Z) for different sizes. If strength is more important than saving weight, go thicker. If lightness and maneuverability matter, find the most efficient profile.

4. Assess Fabrication and Installation Needs

Before choosing an RHS size, think about how it will be fabricated, cut, welded, and installed on-site.

- Is the RHS too large to cut with your current machinery?

- Will it fit into the welding jig or mounting brackets?

- Is the weight manageable for a two-person crew to handle, or will you need lifting equipment?

Also, different RHS sizes respond differently to heat when welding. Thinner-walled sections may warp or distort if not handled carefully. Some projects may benefit from pre-cut or pre-finished RHS to speed up fabrication.

By selecting a size that fits your tools and processes, you save both time and labor costs.

5. Think About Aesthetic Goals and Space Constraints

In architectural or exposed structural elements, looks matter just as much as strength.

- A massive 200×100 RHS might look bulky in a minimalist patio frame.

- A smaller 50×25 RHS could look too weak on a large industrial gate.

The shape and proportion of the RHS should match the visual intent of the design. Smooth flat surfaces of RHS also make it easy to clad or paint, which adds to its appeal in high-visibility projects.

Also take into account:

- Clearance space — Will the section fit into the available space?

- Connection points — Will you have room for bolts, gussets, or fasteners?

Selecting the right RHS size for form and function ensures your finished product is both strong and visually pleasing.

RHS Sizes vs SHS Sizes: What’s the Difference?

It’s easy to confuse RHS with SHS (Square Hollow Sections), but the main difference is the shape:

- RHS: Rectangular profile, longer in one direction

- SHS: Equal width and height, square profile

RHS is typically preferred where directional strength or flat surface mounting is needed, while SHS is better for uniform appearance or when loading is evenly distributed.

Relate article: SHS vs RHS: 7 Key Differences to Pick the Right Steel for Your Project

Where to Buy RHS Steel in the Right Sizes

Finding the exact RHS size you need can be tricky if you’re working with specific dimensions. A good steel supplier will offer:

- Custom cutting services

- Off-the-shelf RHS sizes

- Galvanised or primed options

- Fast delivery to your site

If you’re in Western Australia, we can help! Just send us your drawings or specs — we’ll recommend the right RHS sizes and provide a free, no-obligation quote.

Conclusion: Know Your RHS Sizes to Build with Confidence

Whether you’re a builder, metalworker, or homeowner, understanding RHS sizes is crucial for choosing the right materials. With so many options available, a little knowledge goes a long way in ensuring your project is safe, efficient, and long-lasting.

If you’re still unsure what RHS size is best for your job, don’t guess — ask the experts.

Need help finding the right RHS section for your job? Contact us today and ask about sizes, grades, and custom-cut options.

You can find out more about us at our Fanpage Lintel Steel.