RHS Sections: 6 Advices to Choose the Right RHS for Your Next Project

When it comes to structural steel, RHS sections (Rectangular Hollow Sections) are one of the most widely used and versatile profiles in construction, fabrication, and manufacturing. Known for their clean lines, strength, and excellent load-bearing capacity, RHS steel is a top choice for builders, engineers, and architects across residential, commercial, and industrial projects.

In this article, we’ll explore what RHS sections are, their benefits, common sizes, and how to choose the right RHS section for your application.

What Are RHS Sections?

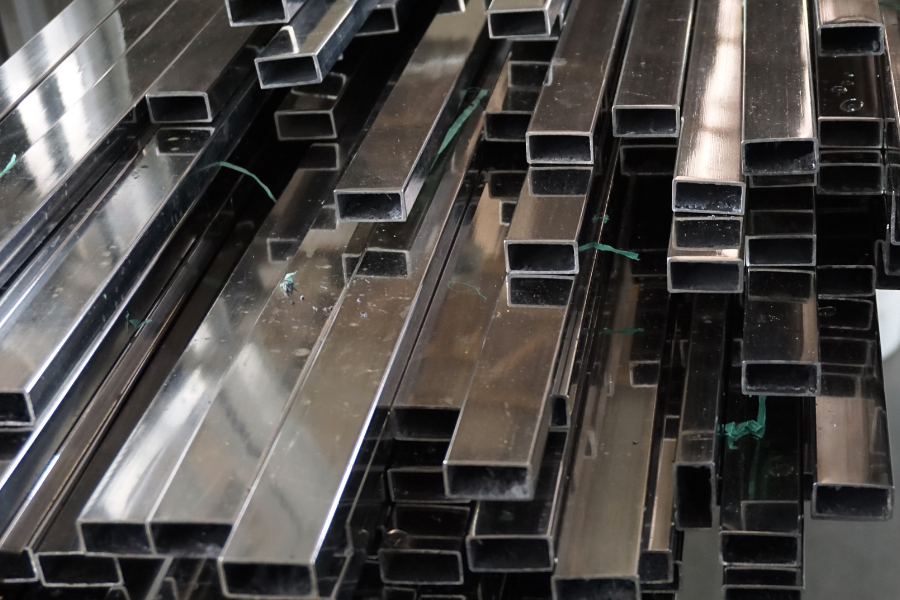

RHS stands for Rectangular Hollow Section, a type of steel tube with a rectangular cross-section. It’s manufactured by cold-forming and welding steel strips into a rectangular shape with consistent wall thickness.

RHS sections are known for their flat surfaces, clean edges, and symmetrical dimensions, making them easy to fabricate, weld, and connect to other components. They offer a high strength-to-weight ratio, excellent resistance to torsion, and uniform load distribution—key characteristics that make them ideal for structural and aesthetic applications alike.

Advantages of RHS Sections

There are several reasons why RHS sections are widely used across the steel industry:

Strength and Stability

Thanks to their geometric shape, RHS sections offer excellent structural integrity. Their flat faces allow for even stress distribution, making them suitable for both vertical and horizontal applications. They also provide strong resistance to bending and buckling.

Aesthetic Appeal

RHS sections are often chosen for visible frameworks in architecture and design projects due to their sleek, modern appearance. They provide a clean, linear look that pairs well with glass, concrete, and other modern materials.

Ease of Fabrication

With flat surfaces and consistent dimensions, RHS steel is easy to cut, drill, weld, and join. This reduces fabrication time and simplifies on-site installation, making it ideal for modular construction.

Versatility

RHS sections are used in everything from fences and gates to high-rise buildings and bridges. Their versatility comes from their wide range of sizes, thicknesses, and steel grades.

Common Applications of RHS Sections

RHS sections are commonly used in a variety of construction and engineering projects, including:

- Structural framing for buildings and sheds

- Columns and posts in architectural design

- Beams in bridges and large-span structures

- Equipment and machinery supports

- Furniture frames and shopfitting

- Fencing, balustrades, and handrails

Because they are available in different thicknesses and materials (such as mild steel, pre-galvanized, and stainless steel), RHS sections can be tailored to suit both indoor and outdoor conditions.

Common RHS Sizes

RHS sections are available in a wide range of dimensions, typically expressed in the format Height x Width x Thickness (in mm). Some common RHS sizes include:

- 50 x 25 x 2.0 mm

- 75 x 50 x 3.0 mm

- 100 x 50 x 3.0 mm

- 150 x 100 x 4.0 mm

- 200 x 100 x 6.0 mm

- 100 x 100 x 5 mm

- 100 x 50 rhs

- 100 x 75 rhs

- 100 x 50 x 3 rhs

- 125 x 75 rhs

- 150 x 50 rhs

- 150x100x5 rhs

- 150×50 rhs

- 150x50x3 rhs

- 200 x 100 rhs

- 200 x 50 rhs

- 200 x 50 rhs steel

- 200x100x6 rhs

- 25 x 50 rhs

- 300x200x10 rhs

Larger or heavier-duty RHS profiles are also available for industrial and commercial use. It’s essential to match the RHS size with your structural requirements, including load-bearing, span length, and connection method.

Choosing the Right RHS Section for Your Project

Selecting the appropriate RHS section for your construction or fabrication needs is a crucial step that directly impacts the structural integrity, cost-efficiency, and longevity of your project. To make the most informed choice, it’s essential to evaluate several technical, environmental, and practical factors. Here’s a deeper look into what you should consider:

1. Load-Bearing Requirements

Start by calculating the expected loads—both static and dynamic—that the structure will carry. The size and wall thickness of your RHS section should correspond to the stress it will encounter. Heavier-duty applications such as structural columns or industrial platforms demand thicker walls and larger cross-sections, while lightweight frames or non-load-bearing applications may only require smaller, thinner sections.

Ignoring proper load calculations can lead to over-specification (which increases cost and weight) or under-specification (which compromises safety and performance). Consulting structural engineers or using structural design software is recommended for precise selection.

2. Environmental Conditions and Corrosion Resistance

The surrounding environment plays a significant role in material longevity. If your project is exposed to harsh weather, moisture, chemicals, or salt air (especially in coastal or industrial zones), you’ll want to use RHS sections that are either pre-galvanized, hot-dip galvanized, or made from stainless steel.

For indoor, dry environments, mild steel RHS may suffice. However, in outdoor applications like fencing, pergolas, carports, or structural frames for marine areas, corrosion resistance is vital. Failing to account for environmental exposure could result in premature rusting, structural degradation, or costly maintenance.

3. Fabrication and Handling Process

Consider the methods you’ll use to cut, weld, drill, and install your RHS steel. Some thicker sections may require specialized tools or high-temperature welding, while lighter RHS profiles can be more easily fabricated with standard shop equipment. Smooth edges, consistent wall thickness, and uniformity across batches will help streamline fabrication and reduce labor time.

Also, if you need to make frequent modifications or site adjustments, thinner sections with higher ductility might offer better flexibility and ease of handling.

4. Aesthetic and Architectural Requirements

For projects where appearance matters—such as architectural features, balustrades, exposed framework, or designer furniture—choose RHS sections that offer clean lines, smooth surfaces, and minimal visible weld seams. Symmetry and precision in size also ensure a consistent visual look, especially when pairing with glass, timber, or aluminum finishes.

Some RHS products even come with pre-coated surfaces or mill-finished options to reduce the need for painting or grinding, saving both time and finishing costs.

5. Local Standards and Regulatory Compliance

Always ensure that your selected RHS sections conform to your region’s building codes, structural standards, and material certifications (such as AS/NZS 1163 in Australia or ASTM standards internationally). These standards govern factors such as:

- Yield strength and tensile strength

- Chemical composition

- Dimensional tolerances

- Weldability and ductility

- Galvanizing and surface coatings

Using non-compliant RHS steel may lead to failed inspections, legal liability, or rework costs. Check that your supplier provides material test certificates (MTCs) or mill certificates for traceability and peace of mind.

6. Budget, Availability, and Lead Time

Beyond technical criteria, practical concerns like cost and availability can influence your decision. Some custom-sized RHS sections or specialty finishes may require longer lead times or minimum order quantities. Balancing ideal specifications with your timeline and budget is key—especially for projects on tight schedules.

Where possible, choose commonly stocked RHS sizes to avoid delays. A reliable local supplier can help you identify the best-fit options without unnecessary over-specification.

Where to Buy RHS Sections

If you’re looking for quality RHS steel, choose a trusted supplier that offers:

- A wide range of sizes in stock

- Custom cut-to-length services

- Fast delivery across your location

- Material certification upon request

- Competitive pricing for bulk orders

RHS steel is an investment in the strength and durability of your project, so it’s worth working with a supplier who understands your technical and delivery needs.

Final Thoughts

RHS sections are an essential component in modern construction and fabrication. Their strength, simplicity, and visual appeal make them a smart choice for builders, designers, and engineers looking for efficiency and performance.

Whether you’re working on a small residential project or a large-scale commercial structure, there’s an RHS size and finish that fits your exact needs.

Looking for RHS sections near you? Contact our team today for a free quote, custom sizes, or expert advice. We’ll help you find the perfect RHS solution to keep your project on time and on budget.

You can find out more about us at our Fanpage Lintel Steel.