RHS Metal: Properties, 5 Uses, and Why It’s a Builder’s Choice

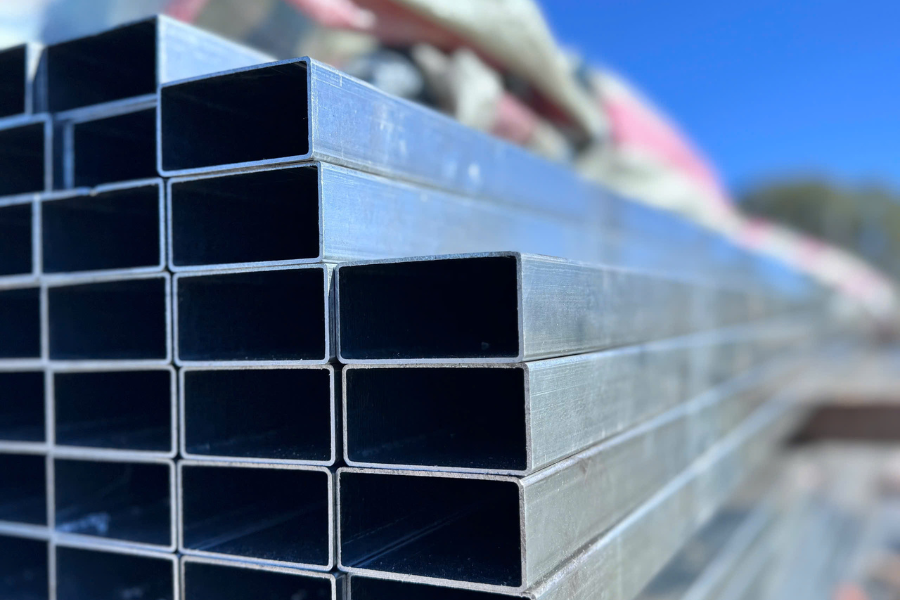

RHS metal, short for Rectangular Hollow Section metal, is a versatile and widely used material in construction, manufacturing, and engineering. Known for its strength, durability, and clean, modern appearance, RHS metal is commonly used in structural frameworks, gates, furniture, and industrial machinery. With a hollow rectangular profile, it offers an excellent balance between weight and load-bearing capacity, making it an ideal choice for both light and heavy-duty applications.

Available in a variety of dimensions, wall thicknesses, and finishes, RHS metal can be customised to suit indoor projects, outdoor installations, and harsh environmental conditions. Whether you’re building a residential fence, fabricating a steel frame, or undertaking a large-scale commercial construction, choosing the right RHS metal ensures your project is safe, efficient, and built to last.

Introduction to RHS Metal

RHS metal refers to Rectangular Hollow Section steel, a popular choice in construction, manufacturing, and engineering due to its strength, versatility, and clean finish. Made by forming flat steel into a rectangular tube and welding it along the seam, RHS offers high load-bearing capacity while maintaining a sleek, modern appearance. Its unique shape makes it especially useful for projects that require both structural stability and design appeal.

From building frameworks to gates, machinery, and architectural features, RHS metal has earned its place as a go-to material for professionals across many industries. It comes in a variety of sizes, wall thicknesses, and finishes to suit different project requirements, including galvanised coatings for enhanced corrosion resistance.

Key Properties of RHS Metal

One of the main reasons RHS is so widely used is its excellent combination of rigidity, uniformity, and ease of fabrication. Its enclosed rectangular profile provides resistance to bending and twisting, ensuring reliable performance in both vertical and horizontal structures.

Notable properties include:

- Uniform Shape – Guarantees consistent strength and a precise, professional appearance.

- High Load Capacity – Strong enough for heavy-duty and structural applications.

- Versatile Finishes – Supplied as raw steel, painted, or galvanised RHS metal for corrosion protection.

- Easy Fabrication – Can be cut, drilled, and welded to suit custom project requirements.

- Excellent Strength-to-Weight Ratio – Provides stability without excessive weight, making it easier to transport and install.

Common RHS Metal Dimensions

RHS metal comes in a wide range of sizes and wall thicknesses to suit different structural needs. Some of the most common sizes include:

| Size (mm) | Wall Thickness (mm) | Common Uses |

| 50 × 25 | 1.6 – 3.0 | Furniture frames, light fencing |

| 75 × 50 | 2.0 – 4.0 | Gates, medium structural work |

| 100 × 50 | 2.0 – 5.0 | Building frameworks, bracing |

| 150 × 100 | 3.0 – 6.0 | Heavy structural supports |

| 200 × 100 | 4.0 – 8.0 | Industrial construction, large beams |

Note: Sizes can vary depending on supplier specifications, and galvanised RHS metal is recommended for outdoor use to prevent rust.

Common Applications of RHS Metal

RHS can be found in many projects due to its adaptability. Common uses include:

Because of its exceptional strength, stability, and clean rectangular profile, RHS metal has become a go-to choice in both light and heavy-duty projects across residential, commercial, and industrial sectors. Its adaptability allows it to be used in everything from precision furniture fabrication to massive structural frameworks.

1. Structural Frameworks and Building Supports

RHS metal is widely used as load-bearing elements in construction. The uniform wall thickness and resistance to twisting make it ideal for:

- Building skeletons for warehouses, factories, and high-rise projects.

- Horizontal and vertical bracing to enhance structural rigidity.

- Roof truss members and mezzanine floor supports.

For civil engineering projects like bridges and pedestrian walkways, RHS ensures stability under heavy loads while offering a streamlined look.

2. Fencing, Gates, and Outdoor Enclosures

RHS metal is a favourite among fabricators for producing modern, durable fencing and gates. Commonly paired with galvanised or powder-coated finishes, it resists corrosion and weathering. Its clean lines make it popular for:

- Residential boundary fencing.

- Commercial security gates.

- Farm and rural property enclosures.

With the right coating, it can withstand decades of exposure to sun, rain, and coastal air.

3. Machinery Frames and Industrial Equipment

In manufacturing plants and workshops, RHS metal provides a stable base for heavy machinery, conveyor systems, and storage racks. Its resistance to vibration makes it a reliable choice for:

- Equipment stands and platforms.

- Shelving for industrial warehouses.

- Frames for automated production systems.

Custom fabrication is straightforward, allowing it to be cut, drilled, or welded to precise measurements.

4. Architectural and Decorative Features

The clean, symmetrical geometry of RHS appeals to architects and designers for both functional and decorative purposes. It is often used in:

- Modern pergolas and outdoor structures.

- Decorative façade frameworks.

- Public furniture such as benches and bike racks.

By combining aesthetics with strength, it allows creative designs without sacrificing safety.

5. Transport, Trailers, and Vehicle Modifications

RHS metal is a staple in the transport sector for building lightweight yet strong frames. Common uses include:

- Chassis construction for box trailers, car carriers, and boat trailers.

- Utility racks for utes and trucks.

- Framework for camper trailers and off-road gear.

Its strength-to-weight ratio means vehicles can carry more payload without unnecessary bulk.

Choosing the Right RHS Metal for Your Project

Selecting the correct RHS metal is essential to ensure the success, safety, and longevity of your project. Because RHS (Rectangular Hollow Section) steel comes in a wide range of sizes, thicknesses, and finishes, taking the time to assess your needs will save you time and money in the long run.

1. Size and Dimensions

The size of your RHS directly impacts its load-bearing capacity and suitability for your application. Common RHS metal dimensions include:

- 50 × 25 × 2 mm – Popular for light frameworks, fencing, and furniture.

- 75 × 50 × 3 mm – Suitable for medium-duty structural work such as gates and pergolas.

- 100 × 50 × 4 mm – Ideal for heavier applications like building columns, mezzanine floors, and industrial machinery frames.

Always match the cross-sectional dimensions to the structural demands of your project.

2. Wall Thickness

Wall thickness determines both the strength and weight of your RHS metal. Thicker walls (e.g., 4 mm and above) offer higher strength for heavy-duty applications but also increase material weight and cost. For light frameworks or decorative purposes, a thinner wall may be sufficient, allowing for easier handling and reduced expense.

3. Coating Type

For outdoor or high-moisture environments, a protective coating is critical. Galvanised RHS metal is one of the most popular options as it resists rust and corrosion for decades, making it ideal for fencing, outdoor furniture, and rural structures. Powder coating can add both protection and colour, enhancing the appearance while extending service life.

4. Compliance with Standards

Ensure that your RHS metal complies with relevant industry and safety standards such as AS/NZS 1163 in Australia. Compliance guarantees consistent material quality, uniform strength, and suitability for structural applications. Using certified RHS metal helps avoid failures that could lead to costly repairs or safety hazards.

5. Purpose and Environment

The end use of your RHS metal should guide your selection. For example:

- In coastal areas, marine-grade galvanised or stainless-coated RHS metal will provide superior corrosion resistance.

- For interior decorative work, uncoated or powder-coated finishes may be sufficient.

- For load-bearing construction, structural-grade RHS metal with verified certification is essential.

6. Fabrication Considerations

Consider how the RHS metal will be cut, drilled, or welded. Thicker sections require more advanced cutting equipment, while thinner sections can be worked with standard tools. Choosing a grade that is easy to fabricate while still meeting strength requirements can improve efficiency and lower labour costs.

By evaluating all these factors—size, wall thickness, coating, compliance, purpose, and fabrication needs—you can confidently choose the right RHS for a durable, efficient, and cost-effective build.

Why RHS Metal is a Cost-Effective Choice

Despite its high performance, RHS metal remains an economical option compared to other structural materials. Its long lifespan, minimal maintenance requirements, and adaptability reduce overall project costs, making it a smart investment for both small-scale builds and major infrastructure works.

Conclusion

RHS metal is a versatile, durable, and cost-effective material that meets the demands of modern construction and manufacturing. Whether you’re building a home, fabricating machinery, or creating architectural designs, RHS metal provides the strength, style, and longevity you need. By selecting the right size, thickness, and finish, you can ensure your project stands the test of time.

You can find out more about us at our Fanpage Lintel Steel.