Hollow Steel Tube: Common Sizes and 6 Essential Buying Guides

From skyscraper frames to simple garden gates, one steel product appears almost everywhere in modern construction: the hollow steel tube. Known for its high strength-to-weight ratio and clean geometric shape, this versatile section has become a favorite among builders, engineers, and fabricators. Available in square, rectangular, and circular profiles, hollow steel tubes are designed to deliver durability while keeping structures lighter and more cost-effective. Whether you are designing a warehouse, building a fence, or fabricating heavy machinery, understanding the types, sizes, and benefits of hollow steel tube can help you make the right choice for your next project.

What is a Hollow Steel Tube?

A hollow steel tube is a type of structural steel section that features an empty space inside, making it lighter while still maintaining excellent strength. These tubes are commonly manufactured in square, rectangular, or circular shapes to suit different building and engineering needs. Because of their durability, they are widely used in construction, fabrication, automotive frames, and even furniture.

Why Choose Hollow Steel Tube?

The reason why builders and engineers often prefer a hollow steel tube is its balance between weight and strength. Compared to solid steel bars, hollow sections reduce overall weight without compromising on structural stability. This not only cuts down on material costs but also makes transportation and installation much easier.

Common Sizes of Hollow Steel Tube

Hollow steel tubes are available in a wide variety of sizes to suit different applications. They are manufactured in square, rectangular, and circular sections, with wall thicknesses ranging from 1.6 mm up to 12 mm or more depending on structural requirements.

Square Hollow Steel Tube Sizes (SHS)

- 20 x 20 mm (light applications such as furniture and fencing)

- 25 x 25 mm

- 30 x 30 mm

- 40 x 40 mm

- 50 x 50 mm (residential frames, gates, and smaller load-bearing uses)

- 65 x 65 mm

- 75 x 75 mm

- 89 x 89 mm

- 100 x 100 mm (common for building frameworks and heavy-duty fabrication)

- 125 x 125 mm

- 150 x 150 mm (industrial structures and large-scale projects)

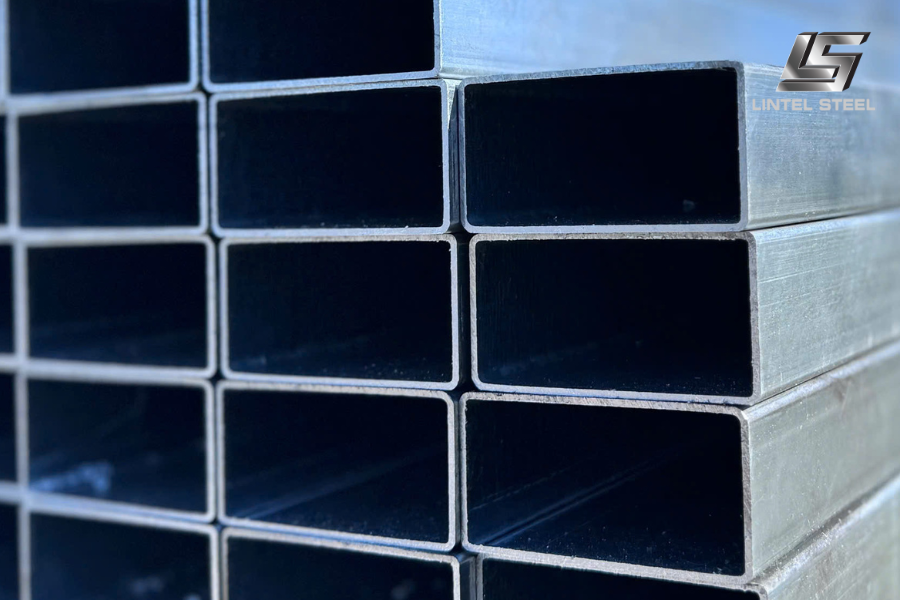

Rectangular Hollow Steel Tube Sizes (RHS)

- 40 x 20 mm

- 50 x 25 mm

- 65 x 35 mm

- 75 x 50 mm

- 100 x 50 mm

- 125 x 75 mm

- 150 x 100 mm (popular for industrial and commercial frameworks)

- 200 x 100 mm

- 250 x 150 mm

- 300 x 200 mm (very heavy-duty load-bearing applications)

Circular Hollow Steel Tube Sizes (CHS)

- Ø 21.3 mm

- Ø 26.9 mm

- Ø 33.7 mm

- Ø 42.4 mm

- Ø 48.3 mm

- Ø 60.3 mm

- Ø 76.1 mm

- Ø 88.9 mm

- Ø 101.6 mm

- Ø 114.3 mm

- Ø 139.7 mm

- Ø 168.3 mm

- Ø 219.1 mm

- Ø 273.0 mm

- Ø 323.9 mm

Thickness Range

- Light hollow tubes: 1.6 mm – 3 mm wall thickness

- Medium structural use: 3 mm – 6 mm wall thickness

- Heavy-duty industrial use: 6 mm – 12 mm wall thickness or more

Applications of Hollow Steel Tube

A hollow steel tube is one of the most versatile steel products on the market. Some key applications include:

- Construction – Used in beams, columns, trusses, and frameworks for residential, commercial, and industrial buildings.

- Fencing & Gates – Lightweight yet strong, perfect for outdoor barriers.

- Automotive – Common in chassis, trailers, and machinery frames.

- Furniture – Provides modern, sleek design with high durability.

- Infrastructure – Bridges, walkways, and towers often rely on hollow tubes for structural integrity.

Advantages of Hollow Steel Tube

Using a hollow steel tube brings multiple benefits:

- High strength-to-weight ratio – ideal for load-bearing structures.

- Cost-effective – less material than solid steel but still durable.

- Easy to fabricate – can be cut, drilled, and welded with precision.

- Corrosion-resistant options – available in galvanised or stainless steel.

- Aesthetic appeal – clean lines and uniform shapes for modern design.

Choosing the Right Hollow Steel Tube

Selecting the correct hollow steel tube is not just about picking a size at random. The right choice ensures your structure is safe, durable, and cost-effective. Here are the most important factors to consider:

1. Size and Dimensions

The first step is to match the size of the hollow steel tube with the load requirements of your project. For light projects such as furniture, gates, or fencing, smaller tubes like 20 x 20 mm or 40 x 40 mm with a 1.6–2 mm wall thickness are often sufficient. For structural frames in residential and commercial buildings, you may need 75 x 75 mm or 100 x 100 mm with a 3–6 mm wall thickness. In heavy-duty industrial or infrastructure projects, large tubes such as 150 x 150 mm or rectangular sections like 200 x 100 mm with 8–12 mm thickness are more appropriate. Choosing the right size helps avoid over-engineering, which saves both material and cost.

2. Material Type

Not all hollow steel tubes are made from the same type of steel.

- Mild steel tubes are affordable and easy to weld, making them ideal for general construction.

- Stainless steel tubes are corrosion-resistant, perfect for environments exposed to moisture or chemicals.

- Galvanised hollow steel tubes are coated with zinc for extra protection, commonly used outdoors, in fencing, and in marine applications.

Understanding which material suits your project environment will extend the lifespan of the structure and reduce maintenance costs.

3. Application

Think about where and how the hollow steel tube will be used. For decorative applications, such as furniture or interior design, appearance and finish matter just as much as strength. For structural use in bridges, towers, or warehouses, strength and durability must take priority. Choosing a lighter section for non-load-bearing use can save money, while heavier-duty tubes are a must for load-bearing frameworks.

4. Finish and Coating

Finishes play a big role in performance, especially outdoors. A painted hollow steel tube offers a basic level of rust resistance, while powder-coated options provide a stronger, longer-lasting layer of protection. For the best results in high-moisture or industrial settings, galvanised hollow steel tubes are recommended, as the zinc coating ensures superior corrosion resistance.

5. Availability and Fabrication Needs

Another important factor is whether your chosen hollow steel tube size is readily available and easy to work with. Common sizes like 50 x 50 mm SHS or 100 x 50 mm RHS are widely stocked and easy to cut, weld, and drill. If your project requires custom dimensions or specialised finishes, you may need to plan for longer lead times.

6. Cost and Efficiency

Finally, balance your project’s budget with long-term durability. While mild steel tubes are cheaper, they may require regular maintenance in harsh environments. Stainless and galvanised tubes may have a higher upfront cost but save money in the long run by reducing repairs and replacements.

Final Thoughts

The hollow steel tube remains a top choice for both builders and manufacturers thanks to its strength, versatility, and cost efficiency. Whether you’re working on a house frame, a warehouse, or even a furniture project, hollow tubes provide the flexibility and reliability that modern construction demands.

You can find out more about us at our Fanpage Lintel Steel.