Rectangular Tubing 6 Professional Selection Tips

If you’ve ever walked past a construction site, stepped into a steel supplier’s yard, or even browsed through a DIY project guide, chances are you’ve come across rectangular tubing without even realising it. This versatile steel product is everywhere—from the strong frames that hold up warehouses, to the trailers on our roads, to the sleek furniture in modern homes. Its popularity comes from a simple combination: strength, clean lines, and adaptability.

What makes rectangular tubing stand out is its ability to balance toughness with design flexibility. Builders rely on it for structural integrity, fabricators love how easy it is to cut and weld, and designers appreciate its sharp, contemporary look. Whether you’re working on a heavy-duty shed in Perth, manufacturing machinery parts, or just putting together a sturdy outdoor frame, rectangular tubing often ends up being the go-to choice.

What is Rectangular Tubing?

Rectangular tubing is a type of hollow structural steel section that has a rectangular cross-section. It is made by forming steel into a rectangular shape and welding the seam, creating a strong, lightweight, and versatile product. Thanks to its durability and straight edges, rectangular tubing is widely used in construction, manufacturing, fabrication, and even decorative applications.

Unlike round or circular tubing, rectangular tubing provides a flat surface and sharper edges, making it especially useful for applications that require flush fitting, welding, and clean structural alignment.

Common Applications of Rectangular Tubing

Rectangular tubing is valued because it combines strength with versatility. Some of the most common uses include:

- Construction frameworks – columns, beams, and support structures

- Manufacturing – machinery frames, conveyor systems, storage racks

- Automotive industry – trailer frames, chassis, and protective barriers

- Furniture and design – tables, shelving, and decorative structures

- Fencing and gates – durable posts and horizontal rails

- Agricultural equipment – durable framework for barns and sheds

Its combination of strength, lightweight design, and easy-to-weld surfaces makes it one of the most adaptable steel products.

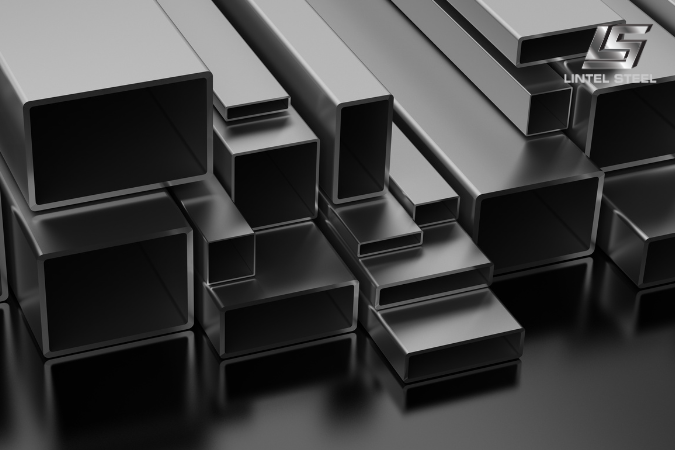

Rectangular Tubing Sizes

Rectangular tubing is produced in a wide range of dimensions, wall thicknesses, and lengths to suit different industries and project requirements. Sizes are usually measured in terms of the outside width, outside height, and wall thickness, while lengths can typically be cut to customer specifications. In Australia, standard mill lengths often come in 6.0m or 12.0m, but suppliers can cut shorter pieces for convenience.

Some common examples include:

- 25 x 12 x 1.6 mm – lightweight use in shelving, light brackets, and decorative items

- 40 x 20 x 2.0 mm – small frames, furniture, or general DIY projects

- 50 x 25 x 2.0 mm – popular for frames, light fabrication, and small trailers

- 65 x 35 x 2.5 mm – ideal for mid-range support in fabrication or small building jobs

- 75 x 50 x 3.0 mm – strong enough for medium-duty construction and manufacturing work

- 100 x 50 x 3.0 mm – one of the most widely used for structural frameworks and supports

- 125 x 75 x 4.0 mm – chosen for agricultural equipment and heavy gates

- 150 x 100 x 5.0 mm – heavy-duty applications including load-bearing frameworks

- 200 x 100 x 6.0 mm – used in industrial machinery frames and large sheds

- 250 x 150 x 6.0–8.0 mm – for bridges, large structural beams, and high-load frameworks

- 300 x 200 x 9.0–12.0 mm – very heavy-duty projects such as industrial plants or large infrastructure

The wall thickness can range from as thin as 1.2 mm (for lightweight indoor furniture or decorative items) to as thick as 12 mm (for heavy industrial frameworks). Thicker walls provide superior strength and rigidity, but also add to the overall weight and cost, which means choosing the right size requires balancing load requirements with budget.

Another important factor is tolerance and compliance with Australian Standards (AS/NZS 1163 for structural steel hollow sections). This ensures that rectangular tubing dimensions are consistent, reliable, and safe for use in structural and load-bearing applications.

In practice:

- Thin-walled rectangular tubing (1.2 mm – 2.5 mm) is best for lightweight structures, display stands, and non-load-bearing applications.

- Medium-walled tubing (3.0 mm – 5.0 mm) is the most common choice for general fabrication, construction frames, and machinery.

- Heavy-walled tubing (6.0 mm – 12 mm) is chosen for high-stress environments like industrial construction, mining equipment, and transport trailers.

By selecting the correct size and wall thickness of rectangular tubing, builders and fabricators can ensure not only safety and structural integrity but also cost efficiency and ease of handling.

Benefits of Using Rectangular Tubing

Choosing rectangular tubing offers several advantages over other materials:

- High strength-to-weight ratio – Provides excellent load-bearing strength without excessive weight.

- Easy fabrication – Straight edges and flat surfaces allow for easier cutting, welding, and joining.

- Durability – Resistant to bending, twisting, and long-term wear.

- Versatility – Suitable for everything from architectural design to industrial machinery.

- Cost-effectiveness – Offers strength similar to solid steel while being lighter and using less material.

Rectangular Tubing vs. Square Tubing

When choosing between rectangular tubing and square tubing, builders and fabricators often consider the load requirements, structural design, and visual finish of the project. While both belong to the family of hollow structural sections (HSS), they serve distinct purposes.

- Rectangular tubing is designed with longer sides and shorter sides, which means its strength is not equal in every direction. The longer side provides better resistance against bending in one plane, making rectangular tubing ideal for applications such as beams, frames, and trusses where directional strength is required. For example, a 150 x 100 mm rectangular tube will have superior bending strength across its depth compared to a 100 x 100 mm square tube of the same wall thickness.

- Square tubing, on the other hand, has equal dimensions on all four sides. This symmetry provides uniform strength in both horizontal and vertical directions, which is perfect for posts, columns, and applications where balanced load distribution is more important than directional resistance. For instance, a 100 x 100 mm square section works well as a vertical support column because it can handle compression and bending evenly on all sides.

Another key difference lies in design aesthetics. Rectangular tubing often delivers a sleek, modern look in architectural projects, especially when used for railings, frames, or furniture. Square tubing, however, is often chosen for simple, balanced designs that prioritise stability over form.

In short:

- Use rectangular tubing for projects needing directional strength (beams, frames, machinery bases).

- Use square tubing for projects needing balanced strength (posts, columns, general support structures).

By understanding these differences, builders can avoid overspending on the wrong material while ensuring that safety and performance standards are met.

How to Choose Rectangular Tubing

Selecting the right rectangular tubing is not just about picking a size off the chart—it’s about balancing performance, cost, and long-term reliability. Below are the main factors to consider, with practical examples:

- Size and dimensions

The length and width of rectangular tubing should match your project’s structural needs. For example, a 100 x 50 mm section might be sufficient for a trailer frame, while a 200 x 100 mm section would be more suitable for industrial machinery bases or shed beams.

- Wall thickness

Wall thickness directly impacts strength and weight. A 2.0 mm wall is great for lightweight projects like furniture or fencing, but a 6.0 mm wall is far better for load-bearing structures such as building frames or bridges. Keep in mind that thicker walls also increase welding time and cost.

- Material type

Mild steel rectangular tubing is affordable, easy to weld, and widely used for general fabrication.

Stainless steel rectangular tubing is ideal for environments exposed to moisture, chemicals, or salt air (such as coastal areas in Perth).

Galvanised tubing offers corrosion resistance and is excellent for outdoor construction and fencing.

- Surface finish

Unfinished black steel is cheaper but requires protective coatings if used outdoors.

Galvanised or powder-coated finishes provide extra durability for long-term projects exposed to weather.

- Compliance with standards

Always check that the tubing complies with AS/NZS 1163 (Cold-formed structural steel hollow sections). Compliance ensures that the tubing has been tested for mechanical strength, toughness, and consistency. This is particularly important for construction projects where safety certification is required.

- Availability and supply chain

Sourcing locally in Perth or other Australian cities ensures fast delivery and access to cutting services. A reliable supplier should also provide mill certificates and material traceability for peace of mind.

Where to Buy Rectangular Tubing in Perth

Builders and fabricators in Perth can source high-quality rectangular tubing from local steel suppliers and distributors. When choosing a supplier, look for:

- A wide range of available sizes and thicknesses

- Compliance with Australian Standards (AS/NZS)

- Options for cutting, coating, or custom fabrication

- Reliable delivery services for large construction projects

Buying locally in Perth ensures faster turnaround times, better technical support, and assurance of quality.

Final Thoughts

Rectangular tubing is one of the most versatile and essential steel products in modern construction, manufacturing, and fabrication. With its wide range of sizes, durable structure, and adaptability, it provides the perfect solution for projects that require both strength and precision. Whether you are building a heavy-duty framework, crafting furniture, or fabricating machinery, rectangular tubing offers an affordable and reliable option.

By understanding the sizes, applications, and benefits, builders and fabricators can choose the right type of rectangular tubing to achieve the best performance in their projects.

Get a quote for rectangular tubing

You can find out more about us at our Fanpage Lintel Steel.