Rectangular Tubing: Sizes and 3 Common Materials

Walk into almost any building site, workshop, or farm shed, and you’ll spot rectangular tubing at work. It might be holding up a framework, forming the skeleton of a gate, or serving as the base of a custom-built trailer. Its appeal isn’t just in the way it looks—straight edges and a clean finish—but in how versatile and reliable it is. Whether you’re a builder putting up a structure, a fabricator working on machinery, or a DIY enthusiast crafting furniture, rectangular tube gives you strength and flexibility in one neat package.

What is Rectangular Tubing?

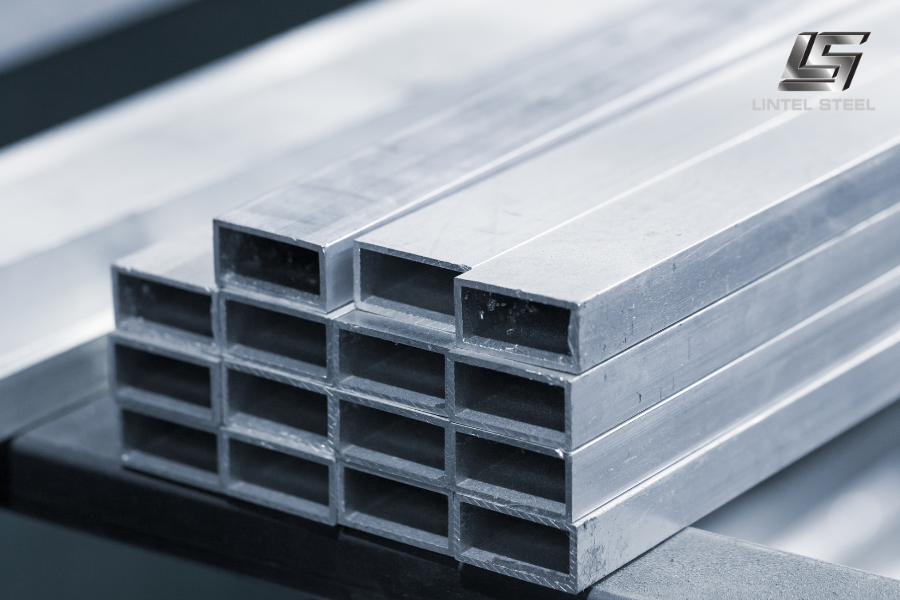

Rectangular tubing (rectangular tube) is a type of hollow structural steel section (HSS) shaped like a rectangle. It is widely used in construction, fabrication, and manufacturing because of its excellent strength-to-weight ratio, clean appearance, and versatility. Unlike solid steel bars, rectangular tube is lighter but still strong, making it a preferred choice for projects that require both durability and cost efficiency.

Common Rectangular Tubing Sizes

Rectangular tubing is manufactured in a wide range of dimensions to suit different applications. Sizes are usually defined by width × height × wall thickness. Some of the most common rectangular tube sizes include:

- 50 × 25 × 2.0 mm

- 75 × 50 × 2.5 mm

- 100 × 50 × 3.0 mm

- 150 × 100 × 4.0 mm

- 200 × 100 × 6.0 mm

- 250 × 150 × 8.0 mm

- 300 × 200 × 10.0 mm

These variations allow fabricators to select tubing that balances weight, strength, and cost. For heavy structural projects, thicker walls and larger dimensions are often chosen, while lighter tubes are common in furniture, fencing, and smaller frameworks.

Key Features of Rectangular Tubing

Rectangular tubing is preferred in many industries because of its unique properties:

- Strength and Stability: The rectangular shape provides excellent load-bearing capacity, especially for horizontal and vertical applications.

- Uniform Shape: Precise dimensions ensure consistent performance and easy fabrication.

- Versatility: Can be cut, welded, drilled, and coated to suit a variety of uses.

- Durability: Depending on material (mild steel, stainless steel, or galvanised steel), it can resist corrosion and last for decades.

Applications of Rectangular Tubing

- One of the main reasons rectangular tubing is so widely used is because it brings together a combination of qualities that are hard to find in other steel products.

- First, there’s the question of strength and stability. Thanks to its flat sides and right-angled corners, rectangular tube performs exceptionally well under both vertical and horizontal loads. That’s why builders trust it in columns, beams, and frameworks where safety and reliability are critical.

- Another benefit is its consistent shape and precise dimensions. Every length of rectangular tubing is manufactured to exact standards, which makes it easy to design with and easy to fit into a wide range of applications. Whether you’re welding it into a machine frame or cutting it for a furniture project, you can count on it to perform exactly as expected.

- Then comes its incredible versatility. Rectangular tube can be cut, drilled, welded, or coated without losing its structural integrity. That flexibility means it works just as well in heavy-duty construction as it does in custom fabrications, decorative pieces, or industrial equipment. It adapts to the project rather than the other way around.

- Finally, there’s the matter of long-term durability. Depending on the material chosen—mild steel, stainless steel, or galvanised steel—rectangular tubing can withstand corrosion, weather exposure, and heavy daily use. Mild steel gives a cost-effective solution for indoor applications, galvanised tubing offers extra rust resistance for outdoor projects, and stainless steel delivers premium strength and longevity in demanding environments.

- Put simply, the features of rectangular tubing make it more than just a steel section—it’s a dependable building block that balances performance, adaptability, and value for money.

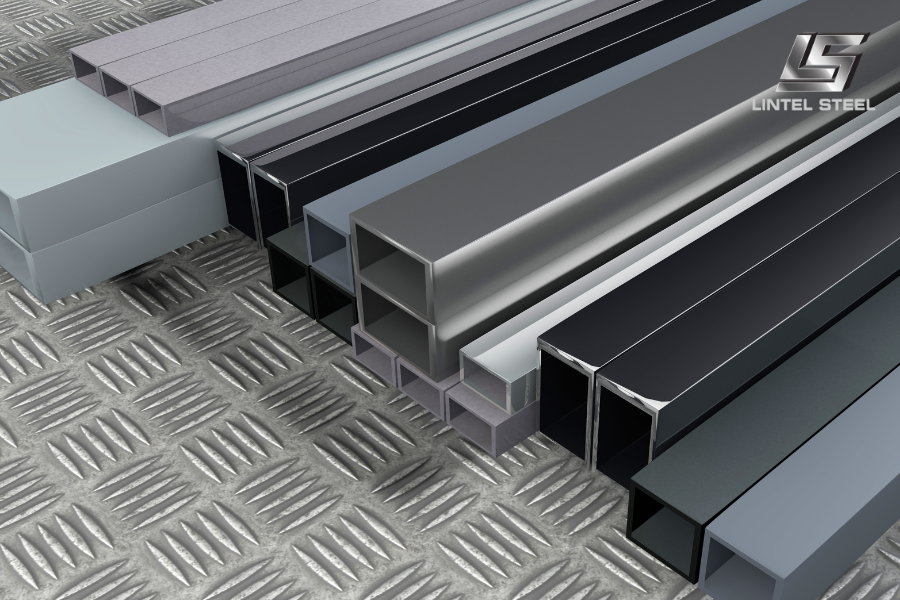

Rectangular Tubing Materials

Not all rectangular tube is the same. The type of steel used in its production makes a big difference in terms of strength, corrosion resistance, appearance, and cost. Depending on where and how you plan to use it, choosing the right material can be the key to a project that lasts decades instead of just years.

Mild Steel Rectangular Tubing

Mild steel is by far the most common material for rectangular tubing. It is affordable, widely available, and easy to weld or cut, which makes it a favourite in general construction and light fabrication. You’ll often find mild steel rectangular tube in frameworks, furniture, fencing, and machinery parts. While it doesn’t have the same corrosion resistance as stainless or galvanised options, it can be painted, powder-coated, or treated with protective finishes to extend its lifespan. Builders choose mild steel when budget and ease of fabrication are top priorities.

Stainless Steel Rectangular Tubing

For projects that demand both strength and resistance to rust, stainless steel rectangular tube is the top choice. This material stands up well in harsh environments, from coastal construction to chemical plants, where moisture, salt, and chemicals can quickly damage regular steel. It is also valued for its modern, polished appearance, making it popular in architectural designs, handrails, and decorative frameworks. While it does come at a higher cost compared to mild steel, the investment pays off in long-term performance and minimal maintenance.

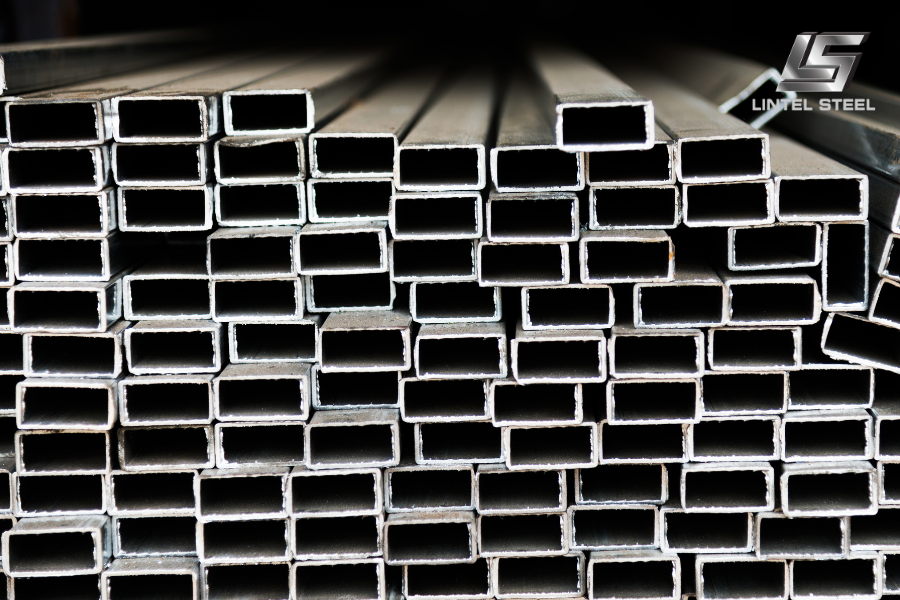

Galvanised Rectangular Tubing

Another popular option is galvanised rectangular tubing, which has a protective zinc coating applied to its surface. This layer acts as a barrier against rust and weathering, making galvanised tubing an excellent choice for outdoor use. It is commonly seen in gates, fences, posts, agricultural structures, and outdoor frameworks where exposure to rain and sun is unavoidable. The zinc coating also provides a level of self-healing, protecting even when the surface is scratched. Builders and fabricators choose galvanised tubing when they need cost-effective durability without the premium price tag of stainless steel.

Which Material Should You Choose?

The best material depends on your project’s environment and purpose:

- Choose mild steel rectangular tubing if you want affordability, easy workability, and plan to apply your own protective finish.

- Choose stainless steel rectangular tube if you need maximum strength, corrosion resistance, and a polished finish for visible or long-term use.

- Choose galvanised rectangular tubing if your project will be outdoors and you want rust protection at a reasonable cost.

By understanding the strengths of each type of material, you can pick the rectangular tube that not only fits your budget but also ensures your project stands the test of time.

How to Choose the Right Rectangular Tubing

When selecting rectangular tube, consider these factors:

- Load requirements – Heavier loads require thicker walls and larger dimensions.

- Environment – Choose galvanised or stainless tubing for outdoor or corrosive settings.

- Aesthetics – For visible structures, stainless steel or powder-coated tubing offers a clean, polished finish.

- Budget – Mild steel tubing is usually the most affordable, while stainless and galvanised options are higher in cost but last longer.

Where to Buy Rectangular Tubing in Perth

Builders, fabricators, and contractors in Perth can source rectangular tubing from local steel suppliers. Many offer custom cutting, fabrication, and delivery services to match project requirements. Whether you need mild steel for general construction, stainless steel for durability, or galvanised steel for outdoor use, choosing a reliable supplier ensures you get high-quality tubing in the right dimensions.

Get a quote for rectangular tubing

You can find out more about us at our Fanpage Lintel Steel.