CHS Steel: 6 Uses and Benefits for Builders

Walk past a building site, a bridge under construction, or even a new warehouse, and chances are you’ll see CHS steel being put to work. Short for Circular Hollow Section steel, this material is one of the most widely used in construction and fabrication because it combines strength with efficiency. Its smooth round profile gives it a modern look, while its hollow core makes it lighter and more economical than solid steel bars. Whether you’re a builder, engineer, or fabricator, CHS is a go-to choice when you need durability, versatility, and reliability in one package.

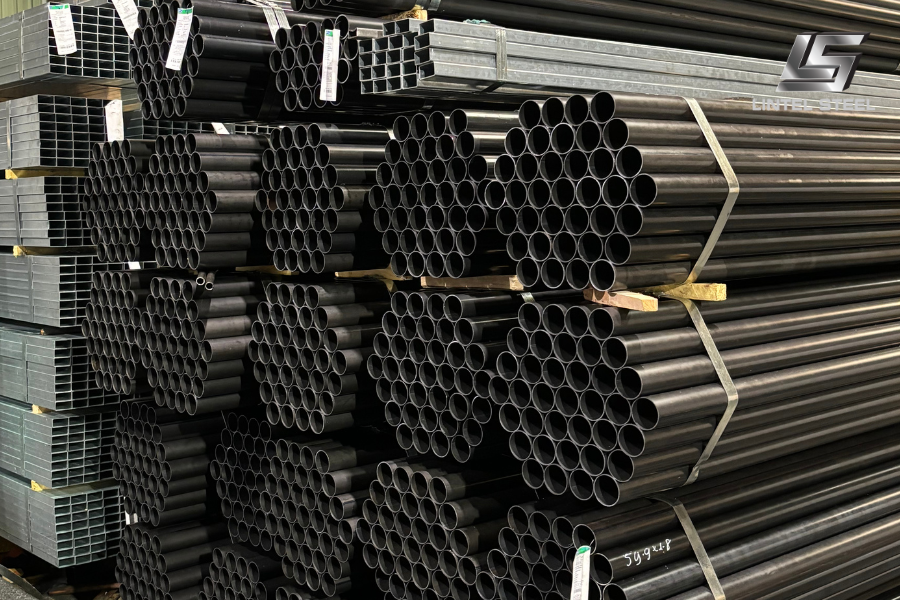

What is CHS Steel?

CHS steel stands for Circular Hollow Section steel. It is a type of hollow steel section shaped into a perfect circle, commonly used in construction, engineering, and manufacturing projects. Unlike solid round bars, CHS provides the same circular appearance while being lighter in weight thanks to its hollow design. This balance of strength and efficiency makes CHS section a popular material across many industries.

Common Sizes of CHS Steel

CHS steel is manufactured in a wide range of diameters and wall thicknesses to suit different applications. Here are some of the common dimensions you will find in the market:

- Ø 21.3 mm × 2.0 mm wall thickness

- Ø 26.9 mm × 2.3 mm wall thickness

- Ø 33.7 mm × 2.9 mm wall thickness

- Ø 42.4 mm × 3.2 mm wall thickness

- Ø 48.3 mm × 3.2 mm wall thickness

- Ø 60.3 mm × 3.6 mm wall thickness

- Ø 76.1 mm × 4.0 mm wall thickness

- Ø 88.9 mm × 4.5 mm wall thickness

- Ø 114.3 mm × 5.0 mm wall thickness

- Ø 139.7 mm × 6.0 mm wall thickness

- Ø 168.3 mm × 6.0–8.0 mm wall thickness

- Ø 219.1 mm × 8.0–10.0 mm wall thickness

- Ø 273 mm × 10–12 mm wall thickness

- Ø 323.9 mm × 12.5 mm wall thickness

These sizes are widely stocked, and heavy-duty projects often require larger diameters with thicker walls for maximum load-bearing capacity.

Applications of CHS Steel

1. Structural Construction

CHS steel is often used in buildings, bridges, and infrastructure. Its smooth circular profile is excellent for columns, braces, and frameworks. Architects also prefer CHS because of its clean appearance, which can be left exposed for a modern industrial look.

2. Scaffolding and Temporary Structures

Because it is lightweight yet strong, CHS steel is widely used in scaffolding systems. It provides stability and safety for workers while being easy to transport and assemble.

3. Mechanical and Engineering Projects

CHS is a common choice for mechanical frames, machinery, and equipment fabrication. Its ability to withstand torsional forces makes it suitable for moving parts and load-bearing assemblies.

4. Transport and Automotive

From truck chassis to protective cages and railings, CHS steel offers durability while keeping weight to a minimum. It is also used in trailers, rail infrastructure, and shipping containers.

5. Fencing, Gates, and Outdoor Structures

CHS tubing is popular in gates, handrails, signposts, and agricultural fencing. When galvanised, it resists corrosion even under harsh outdoor conditions.

6. Pipelines and Fluid Transport

Circular hollow sections naturally lend themselves to the movement of water, oil, and gas. CHS steel pipes are widely used in pipelines where pressure and durability are crucial.

Advantages of CHS Steel

- Strength and Durability

CHS is engineered to handle both compressive and tensile forces, making it suitable for structural projects that need long-term stability. Its circular profile distributes stress evenly, reducing weak points that could otherwise form in angular sections. This makes it an excellent choice for load-bearing applications, such as columns and pipelines, where consistent performance is critical. - Aesthetic Appeal

Beyond raw strength, CHS steel is also valued for its smooth and modern appearance. The rounded shape is often chosen in architectural projects where the structure is left exposed, such as stadiums, bridges, or commercial buildings. Its sleek finish reduces the need for additional cladding or covering, helping designers achieve a professional and minimalist look. - Versatility Across Applications

Available in a wide variety of diameters and wall thicknesses, CHS is adaptable for everything from lightweight fencing to heavy-duty industrial projects. Small-diameter CHS pipes are perfect for furniture, scaffolding, and general fabrication, while larger sections are indispensable in high-rise construction, oil and gas pipelines, and transport infrastructure. - Cost-Effectiveness

Compared to solid round bars, CHS steel offers significant savings because its hollow design reduces the amount of steel required without compromising on performance. This makes it an economical option for large projects where material costs can quickly add up. In addition, its lighter weight often reduces transportation and handling expenses. - Ease of Fabrication

CHS is easy to cut, drill, bend, and weld, making it a preferred material for fabricators and engineers. It can be galvanized, powder-coated, or painted to enhance corrosion resistance and aesthetics. This flexibility allows CHS steel to be customized to fit unique project requirements without sacrificing efficiency or quality. - Durability in Harsh Environments

When treated or galvanized, CHS steel performs exceptionally well in outdoor or marine environments. Its protective coatings extend its lifespan, ensuring that it can withstand exposure to rain, humidity, or saltwater. This makes it highly reliable for long-term infrastructure and industrial installations.

How to Choose the Right CHS Steel

- Load Requirements

Always start by considering the structural load your project will bear. Heavy-duty applications, such as bridges, columns, or pipelines, often require CHS steel with thicker walls and larger diameters. For lightweight applications like furniture or handrails, smaller sizes are more than sufficient. - Environmental Conditions

The environment plays a major role in selecting CHS steel. For indoor applications, standard CHS may be enough. However, for outdoor or marine use, galvanised CHS is the better option because it offers additional protection against rust and corrosion, extending the service life of your project. - Compliance with Standards

It’s crucial to ensure that the CHS you select meets recognized quality and safety standards such as AS/NZS, ASTM, or BS. These certifications guarantee that the steel has been tested for strength, durability, and performance, ensuring reliability in demanding projects. - Project Design and Aesthetics

Your project’s design will also influence the type of CHS steel you need. Larger diameters often provide a more striking and modern visual effect, while smaller sections are subtler and blend into designs. Engineers and architects often balance both the structural and visual aspects when choosing the right section. - Budget Considerations

Finally, weigh your material costs against project requirements. While larger and thicker CHS steel offers more strength, it also comes at a higher price. Assess whether your project truly requires heavy-duty sections, or if smaller, lighter options can achieve the same result more economically.

Conclusion

CHS steel is one of the most reliable and versatile hollow sections available today. With its wide range of sizes, ease of fabrication, and strength-to-weight efficiency, it has become a trusted choice in construction, engineering, and manufacturing worldwide. Whether you need it for pipelines, scaffolding, or building frameworks, CHS delivers long-lasting performance and value.

You can find out more about us at our Fanpage Lintel Steel.