Mild Steel Hollow: Sizes & 8 Must-Know Benefits

When builders and fabricators talk about reliable and affordable structural materials, the mild steel hollow section is almost always at the top of the list. Stronger than timber, lighter than solid steel, and easier to work with than many alternatives, this versatile steel product has become essential in modern construction. Available in square, rectangular, and circular profiles, mild steel hollow offers the perfect balance of strength, cost, and adaptability. Whether you are designing a high-rise frame, manufacturing trailers, or building a simple fence, understanding the benefits and sizes of mild steel hollow can help you make smarter material choices for your project.

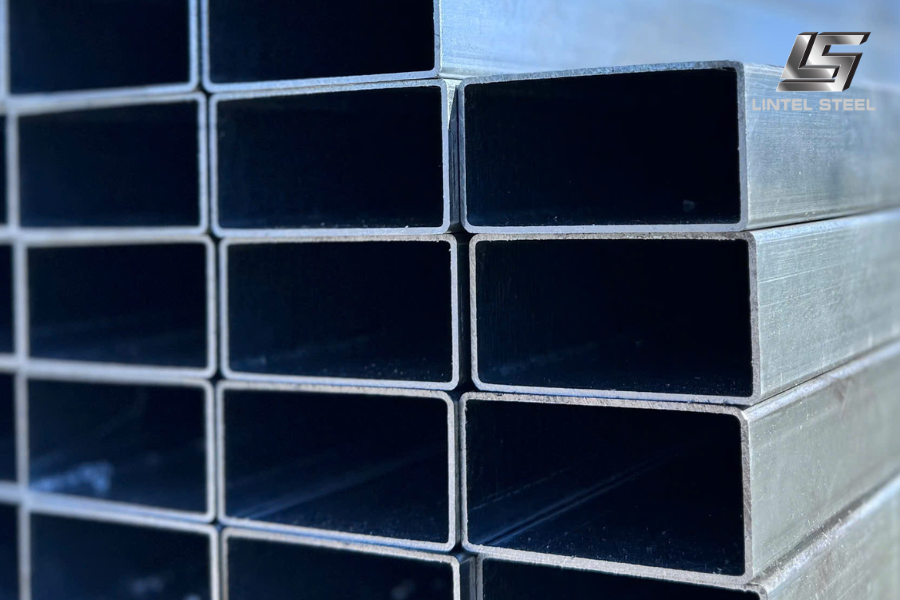

What is Mild Steel Hollow?

A mild steel hollow section is a structural steel product with a hollow interior, commonly manufactured in square, rectangular, or circular shapes. Made from mild steel, these sections are known for being strong, affordable, and easy to work with. Because of their versatility, mild steel hollows are widely used in construction, engineering, automotive, and manufacturing industries.

Why Choose Mild Steel Hollow?

The biggest advantage of mild steel hollow sections is their balance of strength, weight, and cost-effectiveness. Mild steel is easy to cut, weld, and drill, making it suitable for both large-scale projects and small fabrication jobs. Compared to solid steel bars, hollow sections reduce overall material weight while still maintaining high load-bearing capacity.

Common Sizes of Mild Steel Hollow

Mild steel hollow sections are produced in a wide range of sizes and thicknesses to suit different needs. Some common dimensions include:

Square Hollow Sections (SHS)

- 20 x 20 mm – 1.6 mm thickness

- 25 x 25 mm – 2 mm thickness

- 30 x 30 mm – 2 mm thickness

- 40 x 40 mm – 2.5 mm thickness

- 50 x 50 mm – 3 mm thickness

- 65 x 65 mm – 3.5 mm thickness

- 75 x 75 mm – 4 mm thickness

- 90 x 90 mm – 5 mm thickness

- 100 x 100 mm – 6 mm thickness

- 125 x 125 mm – 6–8 mm thickness

- 150 x 150 mm – 8–12 mm thickness

- 200 x 200 mm – 10–12 mm thickness

Rectangular Hollow Sections (RHS)

- 40 x 20 mm – 2 mm thickness

- 50 x 25 mm – 2 mm thickness

- 75 x 50 mm – 2.5–3 mm thickness

- 100 x 50 mm – 3 mm thickness

- 120 x 60 mm – 4 mm thickness

- 150 x 100 mm – 5 mm thickness

- 200 x 100 mm – 6–8 mm thickness

- 250 x 150 mm – 8–10 mm thickness

- 300 x 200 mm – 10–12 mm thickness

- 400 x 200 mm – 12–14 mm thickness

Circular Hollow Sections (CHS)

- Ø 21.3 mm – 2 mm thickness

- Ø 26.9 mm – 2.3 mm thickness

- Ø 33.7 mm – 3 mm thickness

- Ø 42.4 mm – 3 mm thickness

- Ø 48.3 mm – 3.5 mm thickness

- Ø 60.3 mm – 3.5 mm thickness

- Ø 76.1 mm – 4 mm thickness

- Ø 88.9 mm – 4.5 mm thickness

- Ø 114.3 mm – 5 mm thickness

- Ø 139.7 mm – 5–6 mm thickness

- Ø 168.3 mm – 6–8 mm thickness

- Ø 219.1 mm – 8–10 mm thickness

- Ø 273 mm – 10–12 mm thickness

Wall thickness can range from 1.6 mm for light applications to 12 mm or more for heavy-duty projects.

Applications of Mild Steel Hollow

A mild steel hollow is one of the most versatile products in steel fabrication. Common applications include:

- Construction – beams, columns, and frames in residential and commercial buildings.

- Fencing and Gates – lightweight yet strong, suitable for outdoor structures.

- Automotive and Trailers – used in chassis, support frames, and machinery parts.

- Furniture – modern, sleek, and durable design for indoor and outdoor use.

- Industrial Projects – warehouses, factories, and infrastructure frameworks.

Read more: What is Mild Steel RHS? 6 Smart Uses Mild RHS in Construction

Benefits of Mild Steel Hollow

Using a mild steel hollow section provides a wide range of advantages that make it one of the most popular choices in construction and fabrication:

Cost-effective solution

Mild steel hollow is significantly cheaper than stainless steel or galvanised hollow tubes, making it ideal for projects where budget is a priority. Because it requires less raw material than solid steel, it offers excellent value while still providing reliable strength.

Durable and strong

Despite being lightweight, mild steel hollow maintains a high load-bearing capacity. It can handle structural pressure in beams, columns, or frames without excessive bulk, which is why it is commonly used in both residential and industrial construction.

Excellent strength-to-weight ratio

Compared to solid steel bars, hollow sections reduce overall structure weight. This lowers costs in transportation, handling, and installation, while also reducing stress on supporting structures.

Easy to fabricate

Mild steel is one of the easiest materials to work with. A mild steel hollow can be welded, drilled, cut, and bent without difficulty, allowing builders and fabricators to achieve precise shapes and adjustments.

Versatility across industries

From small furniture frames to large-scale infrastructure, mild steel hollow can be used in almost any industry. Its ability to adapt to different designs makes it a truly universal material.

Wide availability in sizes

A mild steel hollow comes in square, rectangular, and circular profiles with a huge range of dimensions. Whether you need a 20 x 20 mm tube for light work or a 300 x 200 mm section for heavy-duty use, there is always a size available.

Customisation options

While mild steel is affordable in its plain form, it can also be painted, powder-coated, or galvanised for additional protection. This gives flexibility depending on whether the project is indoors, outdoors, or in corrosive environments.

Sustainable and recyclable

Mild steel hollow is fully recyclable, meaning old sections can be reused or reprocessed. This reduces environmental impact and makes it a more sustainable choice compared to alternative materials.

How to Select the Right Mild Steel Hollow

Choosing the correct mild steel hollow for your project involves careful consideration of several factors. Making the right choice ensures structural safety, cost efficiency, and long-term performance.

Load requirements

Start by calculating the load your hollow section needs to support. Smaller sizes such as 40 x 40 mm with a 2.5 mm wall may be suitable for furniture or gates, while heavy-duty structures often require 150 x 150 mm or 200 x 100 mm sections with a wall thickness of 8–12 mm.

Application type

For decorative or non-load-bearing uses, lighter hollow sections are sufficient. For structural frameworks, bridges, or warehouses, thicker walls and larger sections are essential.

Environment and exposure

Mild steel in its natural form can rust when exposed to moisture. If the mild steel hollow will be used outdoors or in marine environments, consider galvanising or painting for corrosion resistance. Indoor use may not require additional coatings.

Fabrication needs

Consider how much cutting, welding, or drilling your project requires. Mild steel hollows are easy to process, but thinner walls are faster to work with, while thicker walls may require specialised equipment.

Budget planning

While mild steel is one of the most economical materials, costs increase with section size and thickness. Balancing safety with cost-effectiveness is key. Opting for the right size rather than oversizing can help save significant material costs.

Standards and compliance

Always check whether the mild steel hollow meets local and international standards such as AS/NZS, BS, or ASTM. Certified products ensure consistent quality and safety for your construction project.

Availability and supply

Common sizes like 50 x 50 mm SHS or 100 x 50 mm RHS are typically in stock with most steel suppliers. If your project requires custom or oversized hollows, plan for longer lead times to avoid construction delays.

Final Thoughts

The mild steel hollow is a reliable, cost-effective, and versatile choice for builders, engineers, and fabricators. With a wide range of sizes and shapes, it is suitable for everything from small-scale furniture to large industrial structures. Choosing the right size and thickness ensures durability, safety, and long-lasting performance.

You can find out more about us at our Fanpage Lintel Steel.