RHS in Steel & 7 Common RHS Sizes in Construction

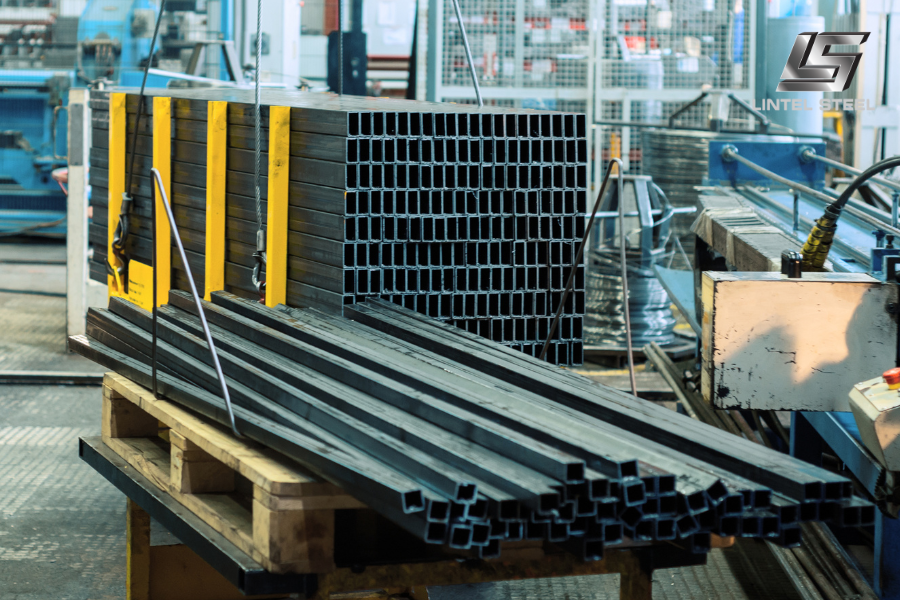

Picture a building site: beams going up, welders at work, and frames being pieced together. At the heart of many of these structures is RHS in steel — a rectangular hollow section designed to deliver strength, precision, and reliability in every project.

What Is RHS in Steel?

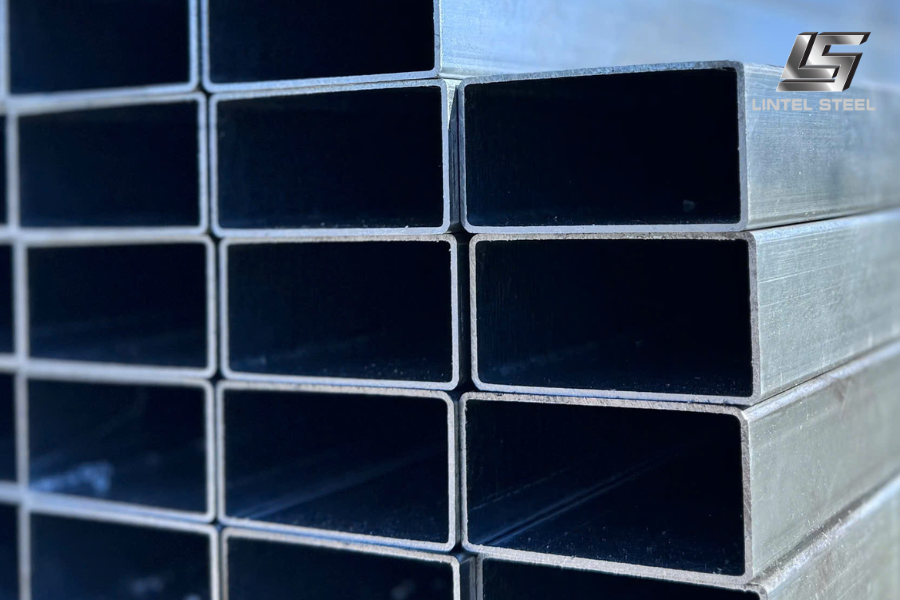

RHS in steel refers to Rectangular Hollow Sections, a popular type of structural steel that features a hollow rectangular shape. Unlike solid steel bars, RHS provides an excellent balance of strength and efficiency. Its flat surfaces make it easy to weld, bolt, and connect to other materials, which is why RHS in steel is widely used in construction, fabrication, and engineering.

Why RHS in Steel Is Popular

The popularity of RHS in steel comes down to three main factors: strength, versatility, and cost efficiency. Because of its hollow design, it can handle significant load-bearing tasks while being lighter than solid steel. This makes it ideal for everything from small residential projects to large-scale industrial buildings. Additionally, RHS in steel can be galvanised, painted, or coated for extra durability in outdoor environments.

Common RHS in Steel Sizes

RHS in steel is manufactured in many sizes to fit different needs. Some commonly available dimensions include:

- 40 x 20 x 2mm – lightweight use, furniture, or display structures.

- 50 x 25 x 2.5mm – gates, frames, and small supports.

- 75 x 50 x 3mm – fencing, bracing, and medium-duty projects.

- 100 x 50 x 3mm – building frames, carports, and structural beams.

- 150 x 100 x 4mm – sheds, warehouses, and roofing support.

- 200 x 100 x 6mm – transport trailers, factory frameworks, and load-bearing walls.

- 300 x 200 x 8mm and larger – major construction, bridges, and heavy-duty industrial fabrication.

Lengths are typically supplied in 6m and 12m options, with wall thicknesses ranging from 1.6mm up to 12mm, depending on the required strength.

Applications of RHS in Steel

The uses of RHS in steel span across industries because of its adaptability:

- Construction: building columns, frameworks, roofing trusses.

- Residential: fencing, gates, pergolas, and home extensions.

- Industrial: warehouses, factories, and storage facilities.

- Transport: truck trailers, machinery frames, and automotive applications.

- Agriculture: sheds, enclosures, equipment supports.

- Furniture & Design: shelving units, tables, and creative metalwork.

Because of its rectangular profile, RHS in steel is especially effective in applications that require flat surfaces for joining and structural alignment.

Benefits of RHS in Steel

- High Strength-to-Weight Ratio – strong enough for load-bearing projects without the excessive weight of solid steel.

- Easy Fabrication – flat sides make welding, cutting, and bolting straightforward.

- Cost-Effective – efficient use of material reduces overall project costs.

- Durable – can be galvanised or coated for superior rust resistance.

- Versatile – suitable for small DIY projects and massive industrial builds alike.

RHS in Steel vs. SHS and CHS

When considering structural steel, three of the most common options are RHS in steel, SHS (Square Hollow Section), and CHS (Circular Hollow Section). Each type has unique characteristics that make it suitable for certain applications.

- RHS in Steel (Rectangular Hollow Section):

RHS is valued for its flat sides and rectangular geometry, which give it strength along one axis. This makes it highly efficient in applications where loads are uneven or directional—such as roofing beams, trusses, or long spans in warehouses. Its flat profile also makes it easier to fix panels, attach bolts, and weld to other components. - SHS in Steel (Square Hollow Section):

SHS is designed for equal strength in both vertical and horizontal directions due to its square shape. This makes it a common choice for columns, uprights, and situations where balanced load distribution is important. SHS is also visually appealing and is often chosen for architectural structures, handrails, or exposed frameworks. - CHS in Steel (Circular Hollow Section):

CHS is different in both appearance and performance. Its round shape provides uniform strength in all directions, which is particularly useful in structures that experience torsional (twisting) forces. It is commonly seen in scaffolding, pipelines, and architectural projects where aesthetics matter. CHS sections, however, are generally harder to weld or fix flat materials onto compared to RHS or SHS.

In short, RHS in steel is the preferred option when strength along one axis and flat surfaces are needed, while SHS is chosen for symmetry and CHS for torsional resistance or curved aesthetics. Many builders combine these sections in one project to achieve the best performance in each area.

Choosing the Right RHS in Steel

Selecting the correct RHS in steel is about more than just picking a convenient size. The decision affects project safety, efficiency, and long-term cost. Here are some extended points to guide you:

- Load Requirements:

For light projects like fencing or gates, smaller RHS sizes such as 50x25x2.5mm work well. For medium-duty work like shed frames or mezzanine floors, 100x50x3mm or 150x100x4mm sections provide the right balance of strength and weight. Heavy-duty structures, such as large warehouses, transport trailers, or bridges, demand larger sizes such as 200x100x6mm or even 300x200x8mm. - Environmental Exposure:

If the project is outdoors, rust is a constant threat. In such cases, using galvanised RHS in steel ensures long-lasting protection against corrosion. In coastal or industrial areas where salt and chemicals accelerate rusting, hot-dipped galvanised RHS is strongly recommended. - Fabrication Needs:

Consider how the steel will be used during fabrication. Thin-walled RHS sections are easier to cut, bend, and weld but may not offer sufficient strength for heavy loads. Thicker RHS provides durability but requires more advanced tools and skilled welding techniques. Choosing a size that matches your fabrication process saves both time and cost. - Budget Considerations:

RHS in steel is more affordable compared to some solid alternatives, but price still varies depending on size, thickness, and whether galvanisation is included. Small sizes may cost less upfront but might not perform adequately in high-stress environments. It’s important to balance initial costs with long-term savings, as galvanised RHS often reduces maintenance and replacement costs over time. - Supply and Availability:

RHS in steel typically comes in 6m or 12m lengths, but many suppliers offer custom cutting to reduce waste. Checking supplier availability before finalising designs ensures your required sizes are in stock and ready for delivery, preventing costly project delays.

Conclusion

RHS in steel is a versatile, durable, and cost-effective solution for countless building and fabrication needs. With its rectangular profile, range of sizes, and excellent load-bearing properties, it continues to be a top choice for engineers, builders, and fabricators. Whether you’re constructing a home, erecting an industrial shed, or designing a trailer, RHS in steel delivers the reliability and efficiency required to get the job done.

You can find out more about us at our Fanpage Lintel Steel.